Introduction

Methodology

Classification system by renovation building element

Methodology of life cycle impact assessment

Establishment of Environmental Impact Coefficients

Conclusions

Introduction

With increasing concerns about global-scale climate change, there is a growing focus on environmental issues through the formulation of specific agreements. Particularly, the problem of global warming is being explicitly addressed, and its impact is considerable on a worldwide scale. Consequently, nations are not only undertaking efforts at the individual country level to reduce greenhouse gas emissions but are also engaging in international agreements to collectively combat global greenhouse gas reduction [1, 2]. The escalating global attention on climate change, intensified by worldwide meteorological anomalies, represents a critical issue that must be addressed to ensure the successful pursuit of the United Nations’ Sustainable Development Goals (SDGs). Despite the greenhouse gas (CO2) reduction efforts of major countries, CO2 emissions continue to rise steadily due to factors such as a fossil fuel-centric energy mix and economic growth in developing nations. As of 2020, South Korea ranked 11th globally in greenhouse gas emissions, emitting a total of 6.9 billion tons of greenhouse gases. Without significant measures, it is predicted that emissions will increase to approximately 8.5 billion tons by 2030 compared to Business-As-Usual (BAU) projections [3].

Consequently, various carbon-centric environmental policies are being implemented in response to climate change, leading to a growing need for reducing environmental burdens in accordance with national-level industrial activities. In line with these efforts, the Korean government has declared its commitment to achieving carbon neutrality by 2050 [4].

Carbon neutrality policies are concentrated on the supply business side, while material demand management and recycling activation policies are neglected. The emergence of various demand management policies is expected to provide environmental information on manufactured products, promote green product consumption, and increase regulatory policies. To achieve carbon neutrality, a change is needed from a workplace-centered management system to a LCA centered management system including embodied carbon emissions. Strengthening requirements for ESG information disclosure, such as International Sustainability Standards Board (ISSB) disclosure standards under International Financial Reporting Standards (IFRS) and EU Sustainability Disclosure Standards (ESRS) The scope of ESG information disclosure includes carbon emissions information including Scope 1, 2, and Scope 3 [5, 6, 7].

In the USA, the White House has initiated the TF project aimed at promoting the procurement of eco-friendly building materials. Ninety-eight percent of federal procurement materials are given priority as low-carbon materials. The government provides support to assist construction raw material manufacturers in minimizing carbon emissions [8, 9, 10]. Effective from 2021, materials surpassing the maximum allowable carbon emissions are prohibited from participating in government bidding. Additionally, carbon labeling certification is mandatory for four types of building materials. Expansion of government policies to gradually improve energy efficiency in new buildings and promote green remodeling of existing buildings. Minimize the energy load required for buildings and minimize energy consumption by utilizing new and renewable energy [11].

In countries that have completed industrialization, there is a noticeable trend where the proportion of environmental load emissions from the construction sector significantly outweighs that of the industrial sector. Presently, there is a rising trend in environmental load due to building sector, necessitating energy-saving measures for existing buildings, constituting 70% of all structures, in addition to energy-saving practices for new constructions [12, 13, 14, 15]. While buildings consume a substantial amount of energy throughout their life cycle, accounting for 37% of the nation’s annual energy consumption, this includes energy consumed during material production and operational phases of building materials. Apartment houses, representing residential buildings, contribute about 40% to annual building energy consumption, making them a significant energy consumer in the life cycle. The energy consumption of apartment buildings is significantly influenced by the envelope system, which interfaces with the ambient air. Therefore, enhancing the efficiency of aging envelope systems is paramount for improving the overall energy efficiency of apartment buildings, especially through green renovation initiatives as depicted in Figure 1[16]. However, current studies on green renovation of apartment houses primarily focus on cost-benefit analyses, such as renewable energy technologies and operational phase energy consumption, neglecting the assessment of intrinsic energy perspectives related to the building materials used in renovation. Additionally, the development of a database and evaluation technology supporting optimal alternatives for energy and environmental performance in improving apartment house envelope systems is still insufficient [17, 18]. Industries in practically every country are increasingly subject to stringent international environmental regulations based on sustainable development principles. Consequently, the construction industry regards sustainable development as a solution to environmental conservation, and endeavors to assess and control the raw materials and energy inputs through environmental product declarations (EPDs) based on life cycle assessment (LCA) as a means of sustainable development. However, at present, studies on the environmental database of renovation construction materials are insufficient to provide adequate support [19, 20].

Therefore, In this study, the goal is to provide stakeholders in green remodeling architecture with an environmental performance information database for key construction materials.. The proposed classification system of construction materials, categorized by designers, aims to provide the necessary environmental information. Additionally, an environmental database is constructed for construction materials where the existing database is unsatisfactory. To achieve this, a classification system for the green renovation system was proposed, selecting representative methods and input materials applicable in actual green renovation building. For the construction of the database, this study built a comprehensive database on the environmental, economic, and energy performances of the envelope classification system, dividing the system boundary. The environmental assessment of building components proceeded by selecting 52 combinations of construction materials for the six major components of the building, specifying size and materials. It was structured to automatically calculate environmental loads when components or construction materials are designated. To support reliable environmental assessments based on material selection, a database (LCI DB) was constructed through a primary hierarchy analysis of detailed construction materials for each component, linking with the life cycle inventory (LCI) databases of construction materials. Even for the same construction material, reflecting the characteristics of input quantities for different parts was made possible, facilitating utilization aspects of assessments and enabling detailed environmental assessment results for each component. National LCI databases were primarily applied for construction material LCI data, supplemented by national construction material environmental information databases and Ecoinvent databases for construction materials not covered in the national LCI databases. Furthermore, for selected component-specific construction materials, a database of characterization coefficients for six major environmental impact categories was constructed using a list analysis of materials with high environmental loads and the characterization factors of ISO 14042. This facilitated the prioritization and comparison of environmentally favorable alternative construction materials by emphasizing materials with significant environmental impacts.

Methodology

Classification system by renovation building element

The assessment of building elements combines the environmental characteristics of building materials, offering several key features. The environmental evaluation of a building is closely linked to the types and quantities of materials employed in its construction. Designers can utilize building element assessments as a support tool to make environmentally friendly and efficient decisions regarding construction materials. When estimating the quantity of construction materials during the design stage, construction element estimation proves more advantageous than the work type estimation applied in traditional life cycle assessment (LCA) techniques. This is particularly beneficial from a user accessibility standpoint, as it simplifies amount estimation and material selection. Moreover, even when the same material serves as the construction material for different building elements, a building element with distinct material characteristics can be added to the database. This approach enhances assessment accuracy, allowing for detailed environmental assessment results for each building element. Given the absence of a specific code or standard that outlines a classification system by building element in South Korea, this study proposes a classification system tailored to the building types prevalent in South Korea, drawing insights from existing international classification systems of building elements. The predominant technique used to assess the environmental performance of buildings is the Whole Life Cycle Assessment method. According to the classification system of building environmental assessment tools by the U.S. Office of Energy Efficiency and Renewable Energy (OEERE), the assessment type following building energy modeling is the Whole Building Assessment based on material and component selections. Representative tools for such assessments include IMPACT for BREEAM support in the UK and ATHENA for LEED support in the US. Here, “building components” refer to parts of buildings such as walls, ceilings, and floors, which consistently serve the same function regardless of building type or design. Assessments based on material and building component selections evaluate the environmental characteristics of building materials, facilitating eco-friendly decision-making by integrating various environmental attributes of materials. This method, based on building materials, progresses through stages of assessment from material level to component level, building level, and ultimately to building environmental certification systems, with the aim of promoting the adoption of environmentally friendly construction materials.

Methodology of life cycle impact assessment

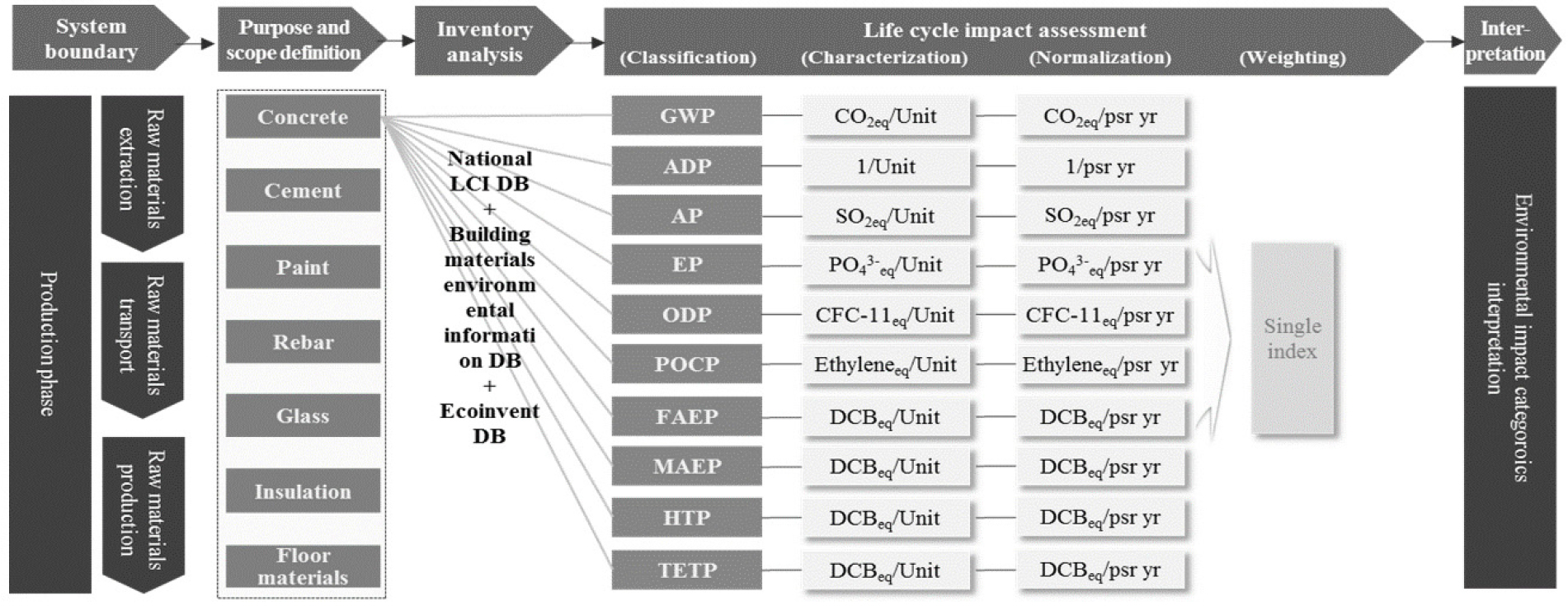

As of January 2023, there are over 16,000 Verified EPDs to EN 15804 for construction products registered globally. With nearly 90,000 EPDs to ISO 21930 and over 25,000 EN 15804 EPDs from verified EPD tools, there are likely close to 130,000 EPDs for construction products globally, as illustrated in Figure 2[19]. As part of a strategic approach to utilize environmental assessment results for construction materials already certified with EPDs issued by the Korea Environmental Industry and Technology Institute (KEITI), this study applied the same LCIA methodology as the current EPD certification system [20].

Specifically, GWP can be estimated using the base substance ‘CO2’ based on the 100-year impact factors suggested by the IPCC guideline. Although different base substances for AP are utilized based on regional characteristics and atmospheric environments, they can be integrated into the single substance ‘SO2,’ as suggested by the universally applicable CML 2002. Similarly, various base substances for EP can be integrated into the single substance ‘PO43-’, following the CML 2002. ODP can be estimated using ‘CFC-11’ as the base substance, relying on impact indexes suggested by the WMO. POCP can be expressed using the single base substance ‘C2H4,’ suggested by the CML 2002. ADP can be estimated using ‘Sb’ as the base substance, following the CML 2002. FATP, MATP, HTP, and TETP can be estimated using ‘DCB’ as the base substance, relying on impact indexes suggested by the CML 2002 [21, 22, 23, 24].

For the LCIA of buildings, The system boundary defining the scope for conducting Life Cycle Assessment (LCA) of construction materials is divided into five stages, encompassing the stages from product manufacturing (A1-A3), construction (A4-A5), use (B1-B7), disposal (C1-C4), up to the calculation of environmental benefits through, as depicted in Figure 3. recycling/reuse of EPD-certified products in Module D. Product manufacturing stage involves the production of raw materials (A1), transportation of raw materials to the construction material production facility (A2), and the manufacturing process of construction materials (A3). Data for assessing the environmental impacts at this stage should ideally be sourced from actual production data of the construction materials. While data for transportation (A2) and manufacturing processes (A3) can be easily managed by companies seeking EPD certification as they typically handle procurement and production data, obtaining data for the production of raw materials (A1) from suppliers might pose challenges. In such cases, utilizing existing Life Cycle Inventory (LCI) databases for raw material production is acceptable Construction stage includes transportation of manufactured construction materials to the construction site (A4) and installation of construction materials (A5). This stage accounts for additional materials, products, energy required during construction, as well as waste and construction debris generated during the process. Environmental impacts are assessed based on scenarios considering potential losses of construction materials during the construction process. Use stage covers the period after the installation of construction materials, encompassing their utilization and maintenance. It includes the use of construction materials, equipment, and services such as heating, ventilation, lighting, water supply, and internal transportation (e.g., elevators and escalators). Data collection for this stage typically relies on scenario-based approaches due to the extended duration required for collecting on-site data in building operations. Disposal stage involves the treatment of waste generated during the demolition process, consumption of materials required for demolition, and environmental impacts arising from energy and water usage. Data for waste disposal should be based on country-specific waste disposal statistics and systems, utilizing individual scenarios based on national waste disposal regulations and systems. Module D provides additional information beyond the boundaries of certified product systems, focusing on the potential environmental benefits of reuse, recycling, and energy recovery. It aims to transparently disclose information regarding potential environmental benefits arising from subsequent product systems using reused products, recycled materials, secondary fuels, and/or products.

In summary, specific data derived from particular production processes, particularly on-site data for target products (A1-A3), should be prioritized for calculating environmental impacts. While data for transportation and manufacturing processes can usually be obtained directly, data for raw material production may be sourced from suitable existing LCI databases. Data for installation, use, and disposal stages are developed based on scenario-based approaches, considering average industry practices for construction and waste disposal [25].

This equation calculates the environmental impact coefficient by summing up the products of the mass of each component or material and its corresponding environmental factor, normalized by the total mass of the construction material. The environmental factors are derived from the LCI Database, providing quantitative data on the environmental impacts associated with each component or material throughout its life cycle , as depicted in Figure 4.

Establishment of Environmental Impact Coefficients

The establishment of environmental impact coefficients involves two essential processes: classification and the collection of environmental impact substances. Drawing on LCA methodologies reported in relevant scientific literature, these processes clarify the influence of each environmental impact substance on the Earth’s environment. Substances are gathered from the Life Cycle Inventory Database (LCI DB) based on environmental impact categories. For example, the IPCC guideline designates CO2 as the base substance as environmental impact substances related to Global Warming Potential (GWP). The classification breakdown for ready-mix concrete 25-210-12 includes 4.10E+02 kg-CO2/m3, 2.10E-09 kg-CFC-11/m3, 2.01E-09 kg-CFC-114/m3, and 3.20E-10 kg-CFC-12/m3

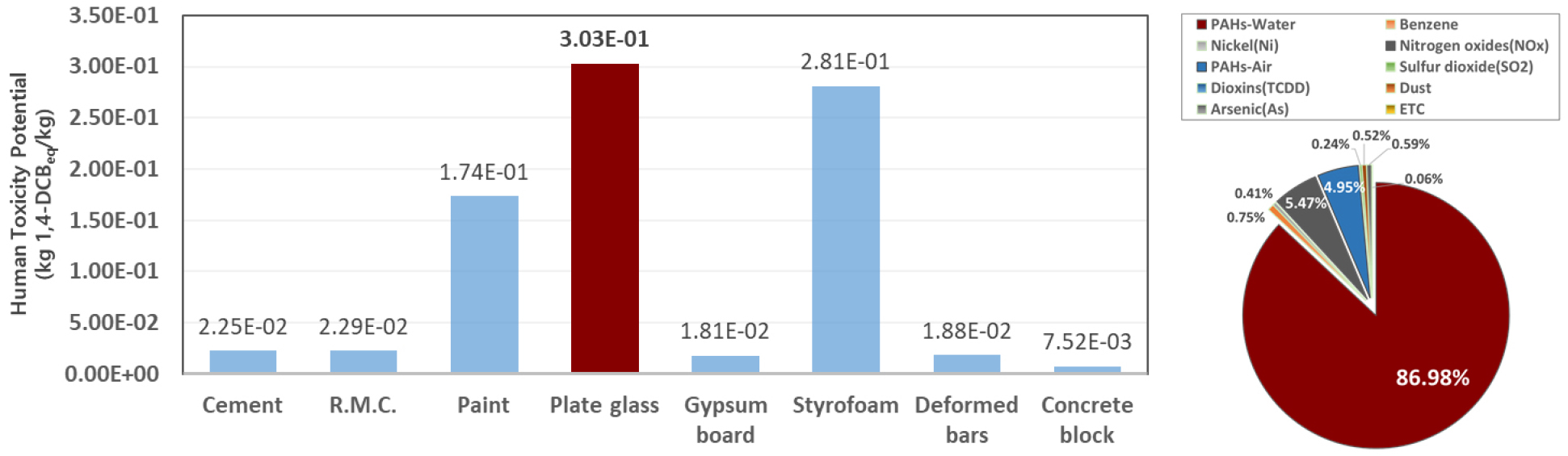

In Table 1, this study categorizes environmental impact substances into their respective environmental impact categories. As depicted in Figure 5, plate glass exhibited the highest level of Human Toxicity Potential (HTP) factor, primarily attributed to the production of Polycyclic Aromatic Hydrocarbons in Water (PAHs-Water) during the manufacturing process. Specifically, PAHs-Water were found to be generated in electric furnaces utilized for the production of glass products, using silica and crushed glass as raw materials. Noteworthy impact factors contributing to HTP include PAHs-Water, Nitrogen oxides (NOx), PAHs-Air, Benzene, and Arsenic. These substances serve as both base substances and environmental impact substances affecting HTP levels. Among them, PAHs-Water stands out as particularly significant due to its notable impact factor in our analysis. After selecting the areas of building components for evaluation, the top environmental impact items for the construction materials inputted, excluding structural materials such as concrete, were analyzed. Insulation materials, cement mortar, and ceiling finishes were identified as major contributors.

Table 1.

Environmental impact coefficient of renovation materials

In particular, for component-specific evaluations, users input area information for each component directly from input material quantity data. This data can serve as foundational material for verifying existing designs against detailed drawings using area calculation reports for future buildings. This straightforward approach to evaluating environmental impact values based on component areas is expected to enhance user-friendliness and efficiency.

Furthermore, users can input construction materials and basic information directly to enable unit assessments for each material, thereby facilitating component-level assessments. Additionally, quantitative evaluations at the building level are achievable through component-level assessments.

Analysis of the environmental impact values for materials inputted per component revealed that structural materials emitted the highest amounts of greenhouse gases, abiotic depletion potential, acidification potential, photochemical ozone creation potential, among others. Environmental impact values derived from building unit assessments showed approximately 16% higher greenhouse gas emissions, 6% lower abiotic depletion potential, 10% lower acidification potential, 10% lower eutrophication potential, 28% lower ozone depletion potential, and 8% higher photochemical ozone creation potential compared to actual environmental impact values of existing buildings. Through material input for each component and subsequent assessments at material, component, and building levels, users can promptly confirm emission quantities based on environmental impact values and derive analysis results.

Environmental impact analysis of ready-mixed concrete reveals a correlation between increased strength and heightened GWP, EP, POCP, and ecotoxicity potential. In contrast, ADP demonstrates an inverse relationship with the strength of ready-mixed concrete. The environmental impact, higher for cement than aggregates, increases with greater amounts of cement. The formulation of cement-ready-mix concrete emerges as a pivotal factor in determining environmental impact, where the composition of alite and belite influences the impact of cement. Moreover, a reduction in aggregates is postulated to reduce ADP, mitigating the high environmental impact associated with ADP.

Conclusions

This study aims to establish environmental impact coefficients for major construction materials in building life cycle assessment, contributing to the development of an environmental effect assessment program. Key conclusions include the selection of 10 environmental impact categories, utilization of the LCI DB and EPD of Building Products, and adherence to ISO 14040. The study aims to effectively support stakeholder decisions in enhancing the environmental performance of buildings and provide a foundation for architects’ voluntary engagement in environmentally conscious activities.

After selecting the areas of building components for evaluation, the top environmental impact items for the construction materials inputted, excluding structural materials such as concrete, were analyzed. Insulation materials, cement mortar, and ceiling finishes were identified as major contributors.

In particular, for component-specific evaluations, users input area information for each component directly from input material quantity data. This data can serve as foundational material for verifying existing designs against detailed drawings using area calculation reports for future buildings. This straightforward approach to evaluating environmental impact values based on component areas is expected to enhance user-friendliness and efficiency.

Furthermore, users can input construction materials and basic information directly to enable unit assessments for each material, thereby facilitating component-level assessments. Additionally, quantitative evaluations at the building level are achievable through component-level assessments.