Introduction

Materials and Methods

Results and Discussion

Experimental Result for Removal of COD

Experimental Result of MLSS and MLVSS

Monod Model for COD

Stover-Kincannon Kinetic Model

Conclusions

Introduction

Discharge of untreated wastewater loaded with organic and nutrient into the environment may contribute to the deficient in the microbial activities of the activated sludge microorganisms during treating wastewater, especially when the influent concentration of the nutrient contaminant is beyond the capacity limits of the microorganisms. However, due to of their solubility in aquatic environments, nutrient contaminants could quickly enter the food chain and accumulate in wide concentrations in the human body. Where they are present in concentrations that exceed the allowed limit, they can cause serious health problems [1]. Consequently, it is of essential significant to treat wastewater containing organic and nutrient contaminants before it is discharged into receiving stream. Treatment of wastewater containing organic and nutrient was accomplished through conventional treatment techniques such as biological systems [2]. Furthermore, rapid urban growth and unhealthy development have put significant stresses on the environment, mainly via the discharge of partially and untreated household wastewaters and sewage [3, 4].Wastewaters are often polluted with substantial amount of regular and unconventional pollutants, such as organic contaminants, nutrients, and toxicants like heavy metals, as well as micropollutants like pesticides, mutagenic chemicals, and so on [5, 6]. The existence of these contaminants in wastewater has a negative impact on aquatic bodies when released without proper treatment. Organics, in particular, deplete oxygen concentration in natural water system and satisfy their biochemical oxygen demand (BOD), disrupting aquatic life [7, 8]. It can also result in the generation of foul-smelling fumes as a result of the anaerobic breakdown of organics [9].

The organic concentrations in municipal sewage are typically high. Human faces, personal care (PC) and housekeeping products contribute nitrogen and phosphorus to domestic wastewater. Thus, aerobic (attached growth system) or/and anaerobic combinations are functional to remove organic from wastewater [10]. Ultimately, domestic and municipal wastewater discharges must be treated before being discharged into waterways [11].

The conventional wastewater treatment system has two main phases. (1) suspended solids generation from dissolved and colloidal solids through biological and chemical means, besides the already established suspended solids; (2) suspended solids separation through mechanical and chemical techniques including floatation, filtration, and sedimentation. Furthermore, biological wastewater treatment plants are mostly intended to remove organic matter through the use of activated sludge microorganisms. In this study, the kinetics of wastewater parameter removal is determined during the rate of removal of Chemical Oxygen Demand (COD).

Materials and Methods

The treatment of Synthetic domestic wastewater treatment was conducted in different flowrate. Wastewater was taking from a sewage treatment plant (STP) of UTP. The reactors were connected by tubing to feed the aeration tank. The biomass was obtained from the return sludge pipeline of the sewage treatment plant (STP). The experiments were then started. Change in the flow rate (5, 10, 15, 20, 25 and 30 L/d) at fixed influent COD concentrations of 550 mg/L. Bioreactor performance was monitored by measuring parameters such as COD and Monod kinetic.

The working sludge age was maintained between the 15 to 25 days. To realize the required sludge, about 10 mL of (MLSS) were taken every two days from the aeration tank for each reactor. All the reactors were run in suspended mode. Reactor A was act as Palm Oil Clinker submerged media in aeration tank and received the feeding from an influent source. Reactor B was act as control and received the feeding from influent sources. Operating parameters monitored during the study includes (COD), (F/M), (MLSS, MLVSS). The tests conducted according to the Standard Methods for the Examination of Water and Wastewater, 4500-NH3 B & C, 15th Edition and APHA Method 4500-NO3: Standard Methods for the Examination of Water and Wastewater [12].

Results and Discussion

Experimental Result for Removal of COD

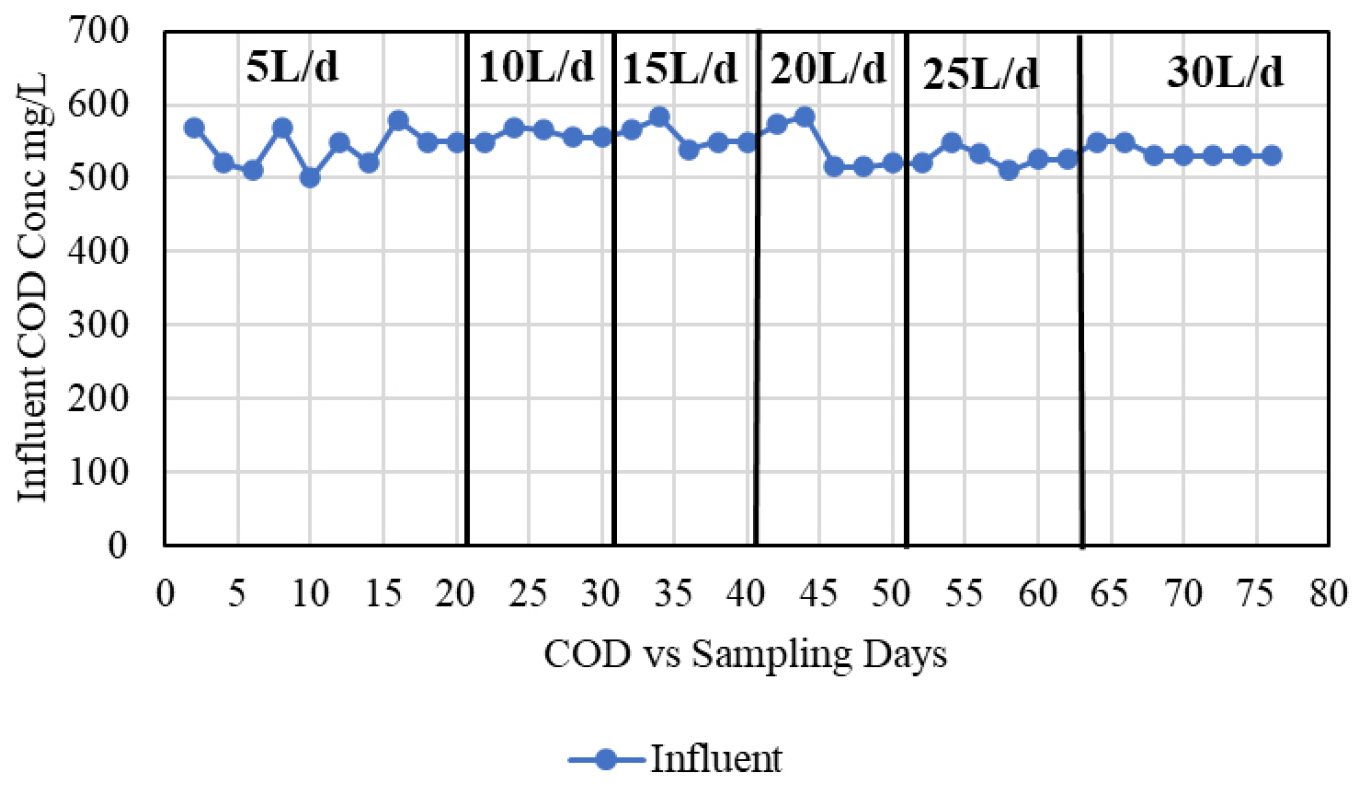

The effluent for both reactors and influent were monitored during the testing time to analysis the substrate used by the biomass. The biomass substrate was monitored in the two reactors (Reactors A and B). Influent and Effluent results of COD throughout the study are shown in Figure 1. The average total influent COD to the reactors was approximately 500±50 mg/L.

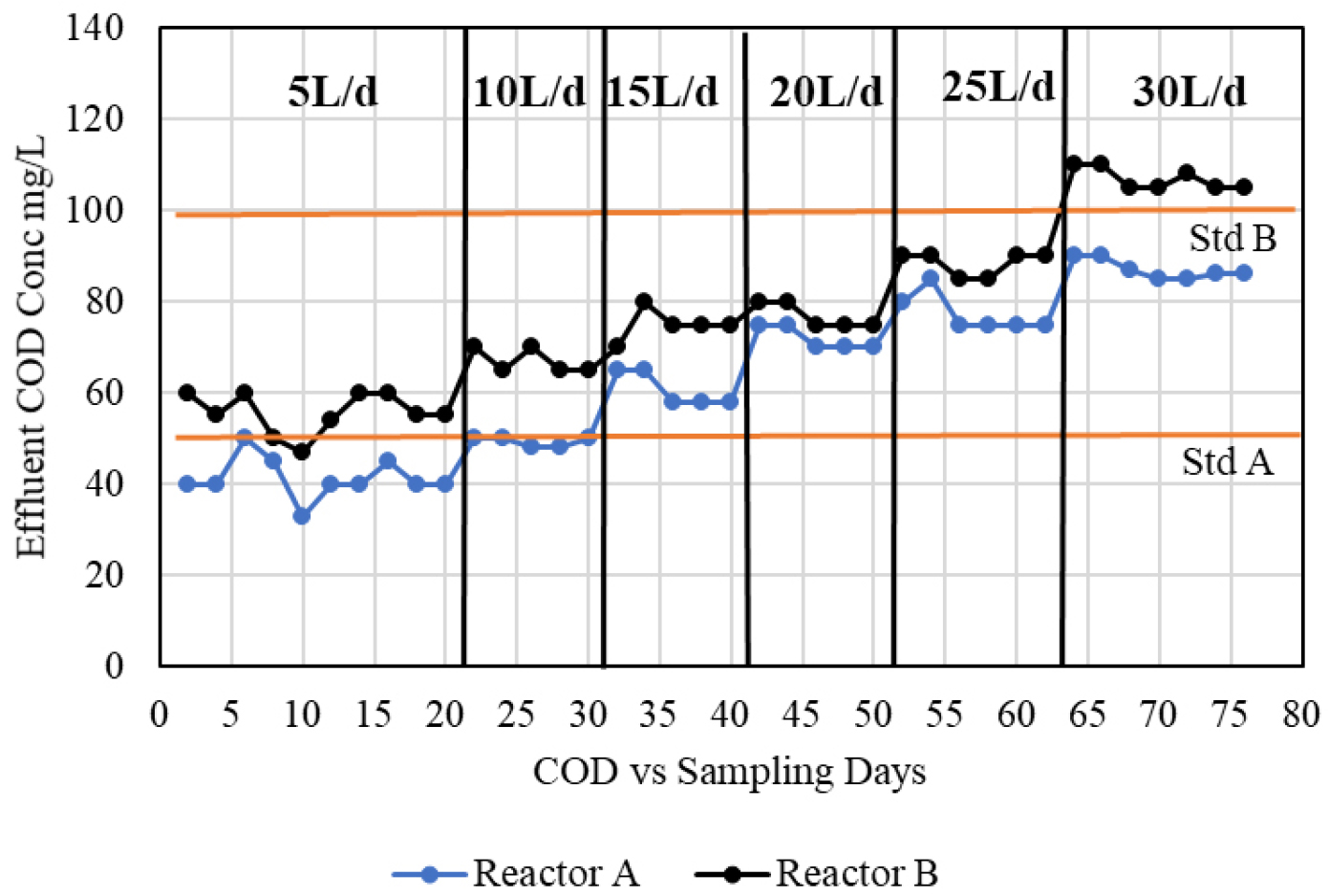

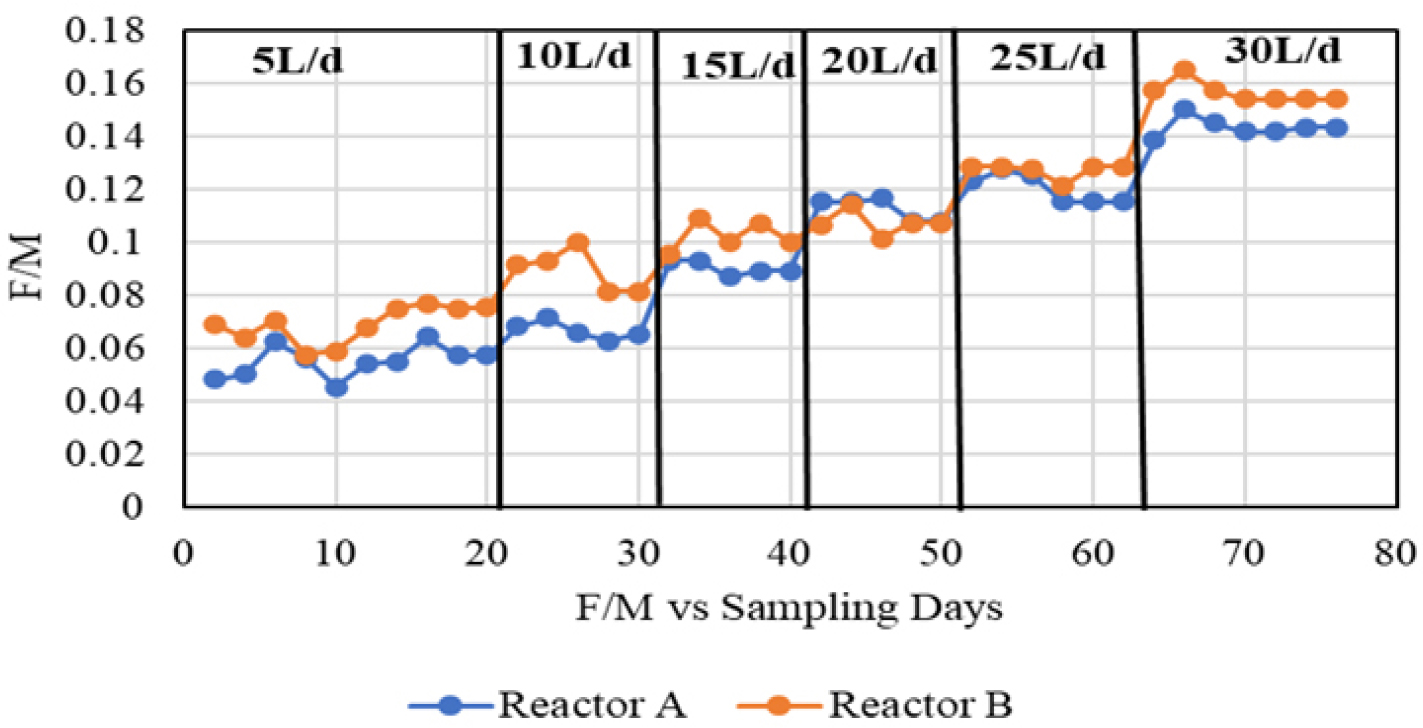

From Figures 1 and 2 it could be noted that from the starting period, there were fluctuations in the effluent of COD concentration from both reactors, even then, organic matter biodegradation has been found out in both reactors. This was predictable as the biomass might have acclimatized to the influent domestic wastewater. From day 16 to day 20, first steady state was noted. The effluent of COD concentration from both reactors was found to be almost at of 30 mg/L to 120 mg/L in all different rates of flowrate experimental. This indicated that the microorganism of organic matter coming from the influent tank, was biologically degrading. The food to microorganisms (F/M) ratio was observed to be 0.05 to 0.15 for the reactor. This is within the range 0.05 < F/M < 0.15 specified for extended aeration [13,14,15]. The stability of COD removal efficiency implies that high metabolic activities occurred within the submerged media. The submerged media supplied a huge surface area for the formation of biofilm which improved the COD removal effectiveness [16]. Observed that increasing flowrate from 5, 10, 15, 20, 25, and 30 L/d caused a changed of COD removal efficiency in the range of 95.6, 94, 91.8, 90.9, 89%, respectively for Reactor A while for Reactor B in the range of 89, 87, 85, 83, 81, 78.1% respectively. The removal of COD in Reactor A was higher compared to Reactor B. The high COD removal could be attributed to organic matter oxidation and endogenous respiration. The readily biodegradable organic matter was oxidized in the aerobic unit which contributed to COD removal and high biomass concentration [16,17,18].

The food to microorganisms (F/M) ratio was observed to be 0.05 to 0.15 for the reactor. This is within the range 0.05 < F/M < 0.15 specified for extended aeration [13,14,15]. The food to microorganism’s (F/M) ratio is shown in Figure 3.

The change of flowrate may have improved substrates and the microorganisms possibilities to close to each other by supplying many reaction sites between substrates and the microorganisms This could simplify the degradation of substrate by microorganisms [19].

The removal of COD in Reactor A was higher compared to Reactor B. The high COD removal could be attributed to organic matter oxidation and endogenous respiration [13]. The readily biodegradable organic matter was oxidized in the aerobic unit which contributed to COD removal and high biomass concentration [17].

Experimental Result of MLSS and MLVSS

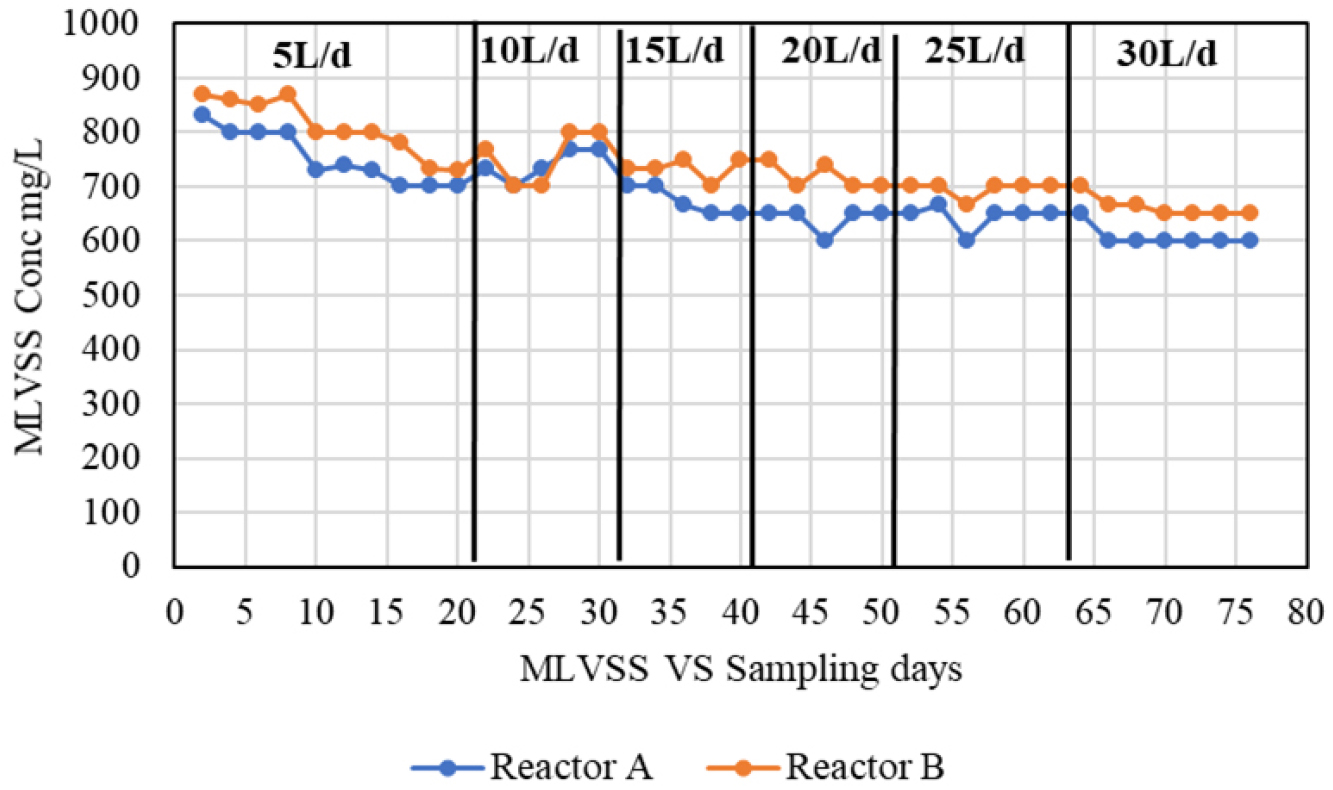

It was observed that COD removal was related to solid production and microbial growth. In all the studies investigated, the changed in substrate removal rate was synchronous with a changed in MLSS and MLVSS concentration due to microbial metabolism, synthesis, and growth Figure 4 is illustrated the MLVSS during the experiments.

Average MLVSS/MLSS ratios of 0.85±0.5 and 0.85±0.7 were obtained for both Reactors respectively.

Monod Model for COD

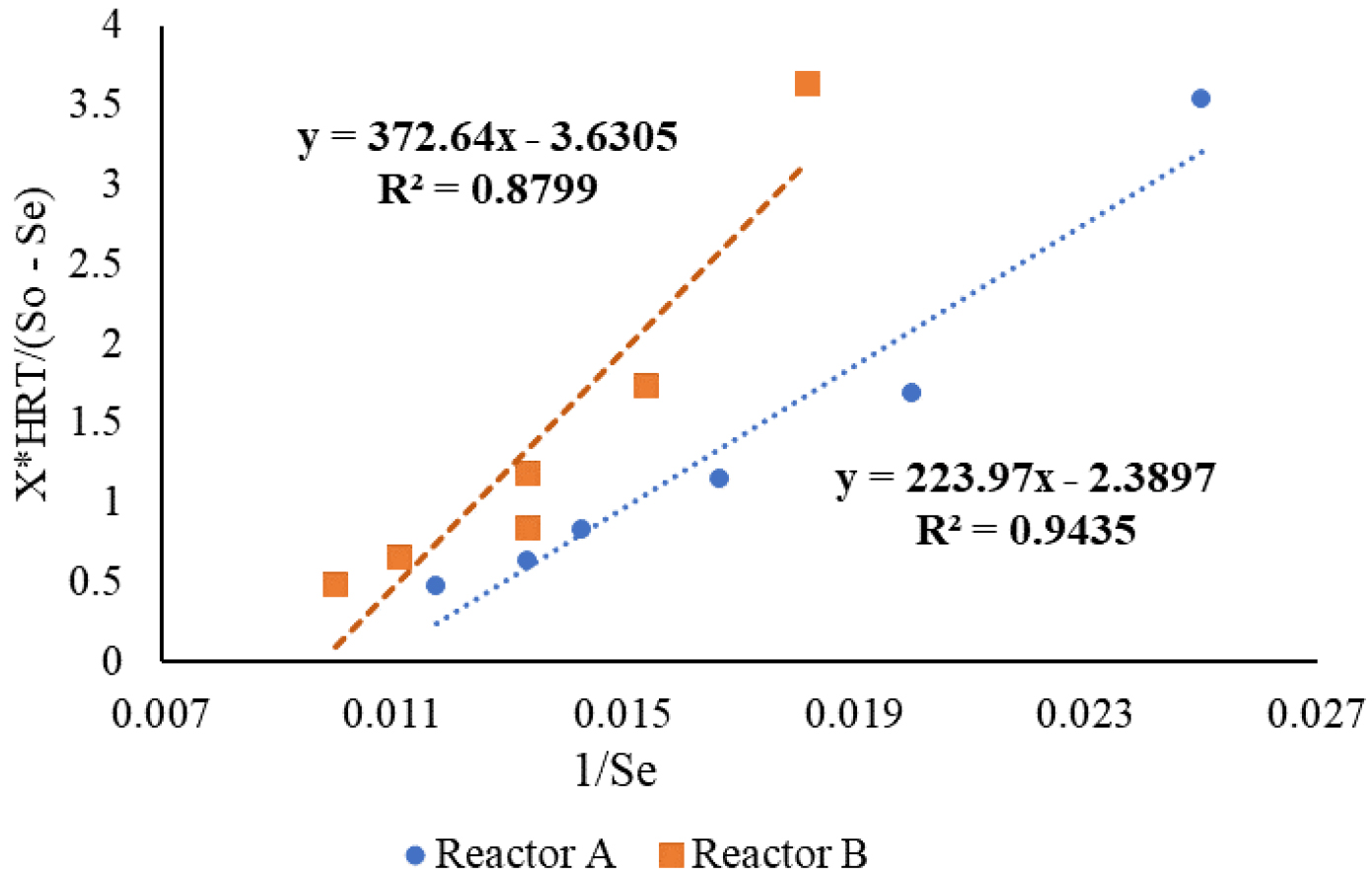

The steady-state data were fitted into the plot of X*HRT/(So-Se) VS 1/Se in Figure 5. The maximum specific growth rate (µmax) and the half-saturation constant (Ks) were then obtained from the intercept and slope of the plot. Ks was obtained as 223.97 and 370 g/m3 for reactor A and B respectively, while (µmax) 0.25 and 0.16 per day with a correlation coefficient (R2) of 0.9435 and 0.8799, for reactor A and B, respectively. The biomass yield (Y) and death rate constant (Kd) are kinetic parameters that can be influenced by the COD concentration in the bioreactor.

According to Hasan et al. a high Kd value indicates that the bioreactor requires a high DO whereas a high Y indicates that a low DO is required [20]. The kinetic coefficient obtained in this study is in close agreement with that of Wong et al. who reported a Y, (Kd) (µmax) and Ks, values of 0.990 g VSS/g COD, 0.024 per day, 0.524 per day, and 203.433 g COD/L for a treating [21]. In contrast, Kaewsuk et al. reported a Y, (Kd) (µmax) and Ks, of 0.2281 g VSS/g COD, 0.1383 per day, 7.42 mg-COD/mg-VSS/d, and 174 mg-COD/L treating dairy wastewater with bacteria [22]. It is well known that a low Ks, the value indicates a higher affinity between microorganisms and substrate [20].

Stover-Kincannon Kinetic Model

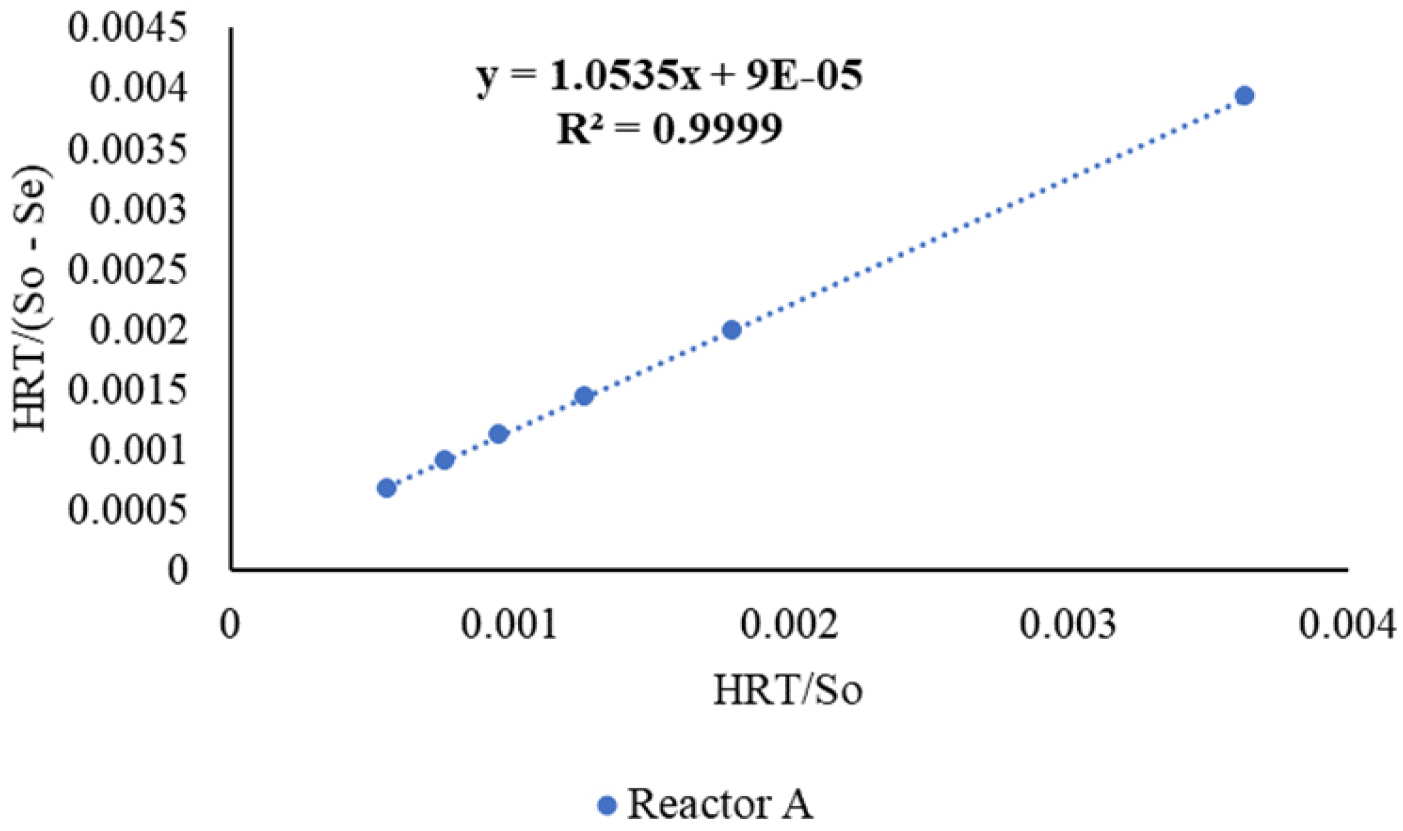

The Stover Kincannon model was improved to obtain the kinetic coefficients of a biofilm. The model expresses the substrate utilization rate as a function of the organic loading rate by molecular kinetics for biofilm reactors [23]. The model is useful for the description of various biological treatment concepts such nitrification, and carbonaceous substrate removal [24].

The highest removal rate constant (µmax) and the saturation value constant (KB) were found out from the intercept and slope of the plot of HRT/ (So - Se) VS HRT/So in Figure 6. the µmax and KB for COD removal were found as 0.0075 g L-1 d-1 and 1 g L-1 d-1, with a correlation coefficient of (R2) 0.999. This observation is in contrast with the report of Priya et al. who obtained a (µmax) and KB values of 3.4 g L-1 d-1 and 4.6 g L-1 d-1 in an upflow fixed film reactor (UAFB) treating paint industry wastewater [25]. Sandhya and Swaminathan, reported a (µmax) and (KB) values of 31.69 g L-1 d-1 and 45.37 g L-1 d-1, respectively in an upflow fixed film reactor treating wastewater [26]. Yu et al. reported a (µmax) and KB values of 83.3 g L-1 d-1 and 85.5 g L-1 d-1 in an filter treating wastewater [24]. In, bioreactor treating simulated textile wastewater, Sandhya et al. obtained a (µmax) and (KB) values of 212 g L-1 d-1 and 22.89 g L-1 d-1, respectively [27]. It is well known that KB value increases with an increase in substrate removal rate concerning initial substrate concentration and microbial population in the reactor [28].

The suitability of the model in this study was continued by the high correlation coefficient.

Conclusions

To assist the conventional wastewater treatment plants to comply with these constraints, it is suggested that a submerged attachment growth media should be incorporated into the conventional treatment system. In main objective of the present study was to establish a comparison between conventional activated sludge system and submerged attached growth activated sludge system for synthetic domestic wastewater treatment. Thus, exploring an appropriate solution to the abovementioned problem.

The performance of palm oil clinker showed high efficiency in removing nutrients and COD more than control in all experimental conditions. The submerged media provided a large surface area for biomass. The submerged media served as a filtration medium for COD removal throughout the study.