Introduction

Material and Methods

Material

Methods for Environmental Impact Category Analysis

Methods for Safety Guard Analysis

Methods for Environmental Costs Analysis

Results and Discussion

Conclusions

Introduction

Recent developments in concrete structures have witnessed an upsurge in the demand for high-strength and high-performance concrete, driven by the construction of tall, large-scale, and specialized structures [1]. Achieving high-performance concrete involves a multifaceted approach encompassing material selection, mix design, and construction techniques. Among these facets, the research pursuit of supplementary cementitious materials stands out as the most actively explored avenue. Common supplementary materials include fly ash, ground granulated blast furnace slag, and silica fume. Typically, a portion of Portland cement is substituted with these supplementary materials to enhance the concrete’s properties. The utilization of supplementary materials not only allows for the attainment of properties akin to those of cement-only concrete but also yields advantages such as reduced heat generation and enhanced long-term strength and durability, particularly in the context of large-scale structures [2, 3].

Conversely, silica fume has conventionally served as a supplementary material for high-strength concrete; however, it has faced criticism due to its elevated cost. Recent research endeavors have refocused attention on metakaolin as a cost-effective alternative with comparable performance attributes [4]. Metakaolin is derived from the controlled thermal treatment of uniformly composed kaolin, followed by grinding to achieve a specific particle size. In the short term, metakaolin expedites the chemical reactions by promoting the formation of ettringite and activating the primary cementitious mineral, alite, resulting in accelerated early strength development [5]. Moreover, over the medium to long term, metakaolin contributes to the compaction of the concrete matrix through pozzolanic reactions with calcium hydroxide in cement, thereby enhancing both strength and durability. Furthermore, metakaolin not only augments the concrete’s properties as a supplementary material but also mitigates its environmental impact by reducing carbon emissions, rendering it an environmentally conscientious option. The International Council for Research and Innovation in Building and Construction has launched a CIB W80/RILEM 175-SLM committee to establish TC59/ SC13/WG9 Service Life Design on the basis of the support of CIB·RILEM, thereby creating a new ISO standard for durability design. After this, in TC98/SC2, the international standards proposal ISO 13823:2008, was announced to recommend a procedure that secures durability, and studies on the establishment of standards for life cycle assessment and environmental impact have been underway. Nonetheless, comprehensive quantitative assessments of its environmental impact characteristics remain limited.

Consequently, this study endeavors to conduct an environmental performance analysis of concrete employing metakaolin as a substitute for cement. Through an exhaustive literature review, the study explores concrete mix designs incorporating metakaolin and limestone, employing a rigorous assessment methodology to quantitatively evaluate six environmental impact categories, four safety measures, and environmental costs, including reductions in carbon emissions.

Material and Methods

Material

Table 1 presents the mix designs of concrete incorporating metakaolin and limestone investigated through the literature review [6]. In this study, we analyzed the environmental performance of the seven concrete mix designs shown in Table 1. Here, PC represents a mix where only ordinary Portland cement is used, while LS, MK, and B respectively denote mixtures incorporating limestone, metakaolin, and a combination of limestone and metakaolin, with the numbers following the letters indicating the substitution rates of the respective supplementary materials.

Table 1.

Concrete Mixture Design

Methods for Environmental Impact Category Analysis

The environmental impact categories represent a list of Earth’s environmental changes resulting from human actions or technologies, and they are quantified and categorized. They include Global Warming Potential (GWP), which pertains to the phenomenon of increasing global average surface temperatures, as well as Acidification Potential (AP), Eutrophication Potential (EP), Ozone Layer Depletion Potential (ODP), Photochemical Oxidation Potential (POCP), and Abiotic Depletion Potential (ADP). The impact of these categories can be quantitatively assessed through the Life Cycle Impact Assessment (LCIA) methodology.

In this study, considering the criteria for selecting Life Cycle Inventory (LCI) databases outlined in ISO 14040, we applied specific material LCI databases, prioritized in the following order: Korean LCI DB from the Ministry of Trade, Industry, and Energy in South Korea [7], the National DB on Environmental Information of Building Materials from the Korea Institute of Civil Engineering and Building Technology [8], the international CML2 Database [9], and research reports [10]. Environmental impact factors were compiled as presented in Table 2. Furthermore, quantitative evaluations of environmental impacts within the six environmental impact categories were conducted for each mix design by multiplying the usage quantities of individual raw materials with their respective environmental impact factors.

Table 2.

Environmental Impact Factor

| Classification | Unit | Cement | Water |

Fine Aggregate |

Coarse Aggregate | Metakaolin | Limestone | Admixtures |

| GWP | kg-CO2eq/kg | 9.48E-01 | 1.53E-03 | 2.29E-03 | 7.77E-03 | 4.21E-01 | 2.53E-03 | 2.05E-03 |

| AP | kg-SO2eq/kg | 1.28E-03 | 2.98E-06 | 6.51E-06 | 1.36E-05 | 1.03E-03 | 6.42E-06 | 5.45E-08 |

| EP | kg-PO43-eq/kg | 1.34E-04 | 5.16E-07 | 1.14E-06 | 2.52E-06 | 6.47E-05 | 1.21E-05 | 5.21E-07 |

| ODP | kg-CFC11eq/kg | 1.70E-08 | 1.45E-12 | 1.30E-10 | 2.10E-11 | 3.98E-08 | 3.32E-10 | 2.17E-11 |

| POCP | kg-C2H4eq/kg | 2.60E-03 | 1.20E-06 | 1.91E-06 | 6.08E-06 | 5.20E-05 | 6.49E-06 | 5.45E-08 |

| ADP | kg-Sbeq/kg | 2.70E-03 | 8.07E-06 | 1.40E-05 | 5.06E-05 | 3.39E-03 | 1.51E-05 | 4.45E-05 |

| Source | ① | ① | ② | ② | ③ | ① | ④ | |

①: Korean LCI DB of the Ministry of Trade, Industry and Energy and the Ministry of Environment of South Korea; ②: National Database on Environmental Information of Building Materials of the Korean Institute of Civil Engineering and Building Technology; ③: CML2 Database; Heath et al., Minimising the global warming potential of clay based geopolymers, Journal of Cleaner Production 78 (2014), pp. 75-83; ④: Final Research Report entitled “Development of Mix Design Technique of Concrete for Reduction of CO2 Emissions”, Hanyang University, 2015

Methods for Safety Guard Analysis

Safety guard refers to the aspects of the environment that humanity should protect from an environmental ethics perspective, and these items can be categorized into human and ecosystem components. In this context, the human component is further divided into human health, which relates to the well-being of individuals in terms of leading a healthy life, and social assets, which pertain to the assets that sustain human societies. The ecosystem component can be subdivided into biodiversity, which involves the conservation of flora and fauna, and primary production, which represents the essential conditions necessary for sustaining biodiversity [11].

On the other hand, the damage index represents quantitative indicators of the harm inflicted upon the four protection targets due to environmental impacts. Specifically, human health is assessed using disability adjusted life year (DALY), which quantifies the period of disability and illness leading to death or non-lethal impairments as the damage indicator. Social assets encompass the economic costs associated with the inhibition and depletion of crops, fisheries, forest resources, mineral resources, and fossil fuels. Biodiversity is evaluated based on expected increase in number of extinct species (EINES), which reflects the expected increase in the number of extinct species among relevant flora and aquatic organisms. Primary production utilizes net primary production (NPP) as the damage indicator, representing the amount of organic matter (kg/m2·yr) produced through photosynthesis by terrestrial plants and marine plankton. These damage indicators for each protection target can be evaluated using an endpoint-level life cycle impact assessment methodology, as systematized in Table 3, which utilizes scientific research findings to quantify damage indicators for each protection target [11].

Table 3.

Safety Guards and Damage Factor

Methods for Environmental Costs Analysis

Environmental costs refer to the quantified environmental issues at the endpoint level, which are caused by environmental impacts, categorized into safety guards from an environmental ethics perspective. These costs are translated into monetary values. Such environmental costs can be determined using a monetary valuation-based damage assessment life cycle assessment model.

In this study, we established environmental cost values per functional unit for each building material using the KOLID model, which is a monetary valuation- based damage assessment life cycle assessment model developed by the Ministry of Environment in South Korea [11]. KOLID quantifies damage for 16 endpoints, including cancer, heat stress, infectious disease, skin cancer, cataract, and others, across six environmental impact categories: GWP, AP, EP, ODP, POCP, and ADP. It evaluates four protection targets: human health, social assets, biodiversity, and primary production. This study assessed environmental costs through marginal willingness to pay (MWTP) for the four safety guards, as presented in Table 4.

Table 4.

Marginal willingness to pay (MWTP) by Safety Guards

Results and Discussion

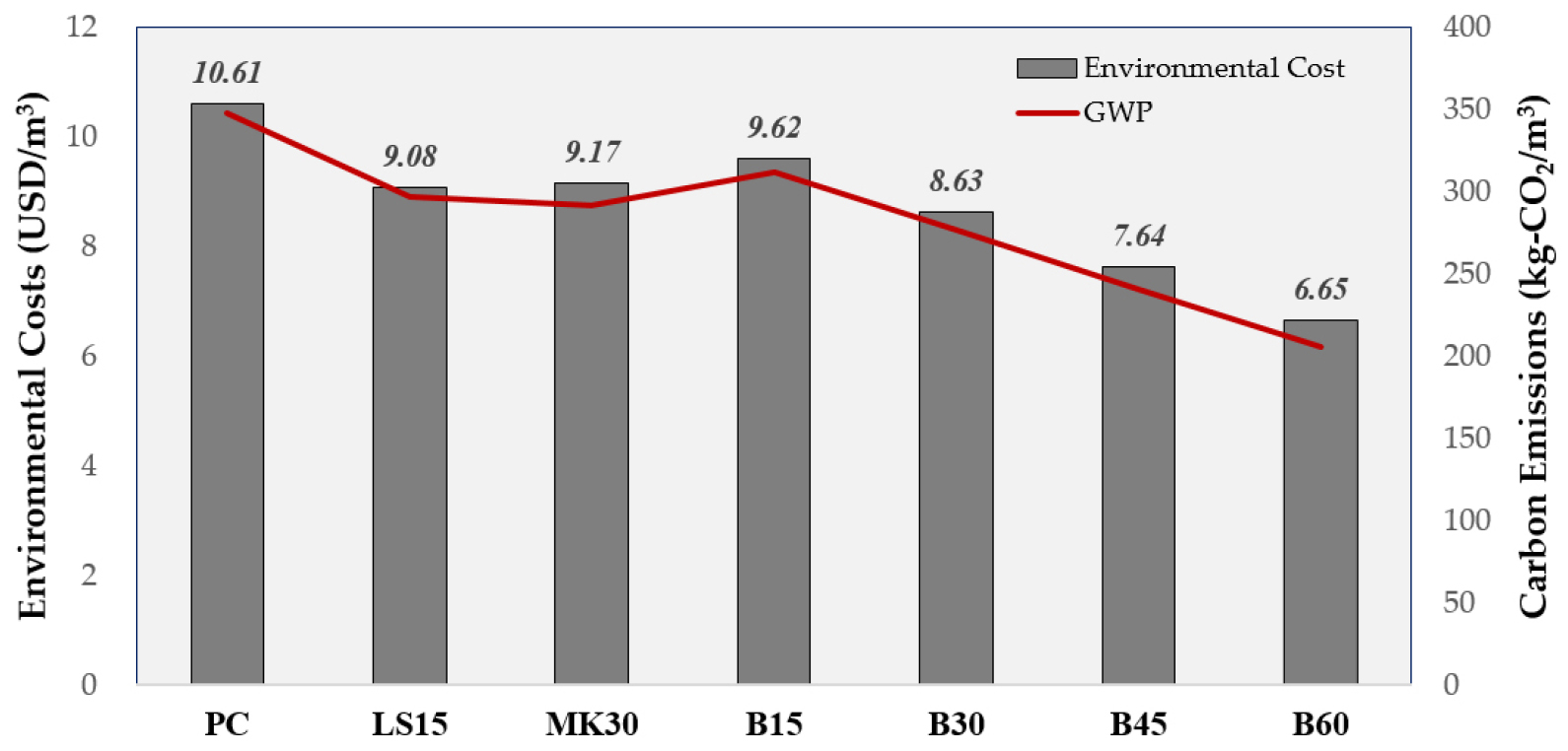

Figure 1 illustrates the results of the GWP assessment based on concrete mixture design. According to Figure 1, among the seven concrete mixtures selected in this study, PC exhibited the highest GWP value at 347.74 kg-CO2eq/m3, while B60 showed the lowest GWP at 205.40 kg-CO2eq/m3. Particularly, the cement usage was in the order of PC, B15 = LS15, MK30 = B30, B45, B60, and it was evident that there is a significant correlation between GWP and cement usage, with GWP following the sequence of PC, B15, LS15, MK30, B30, B45, and B60.

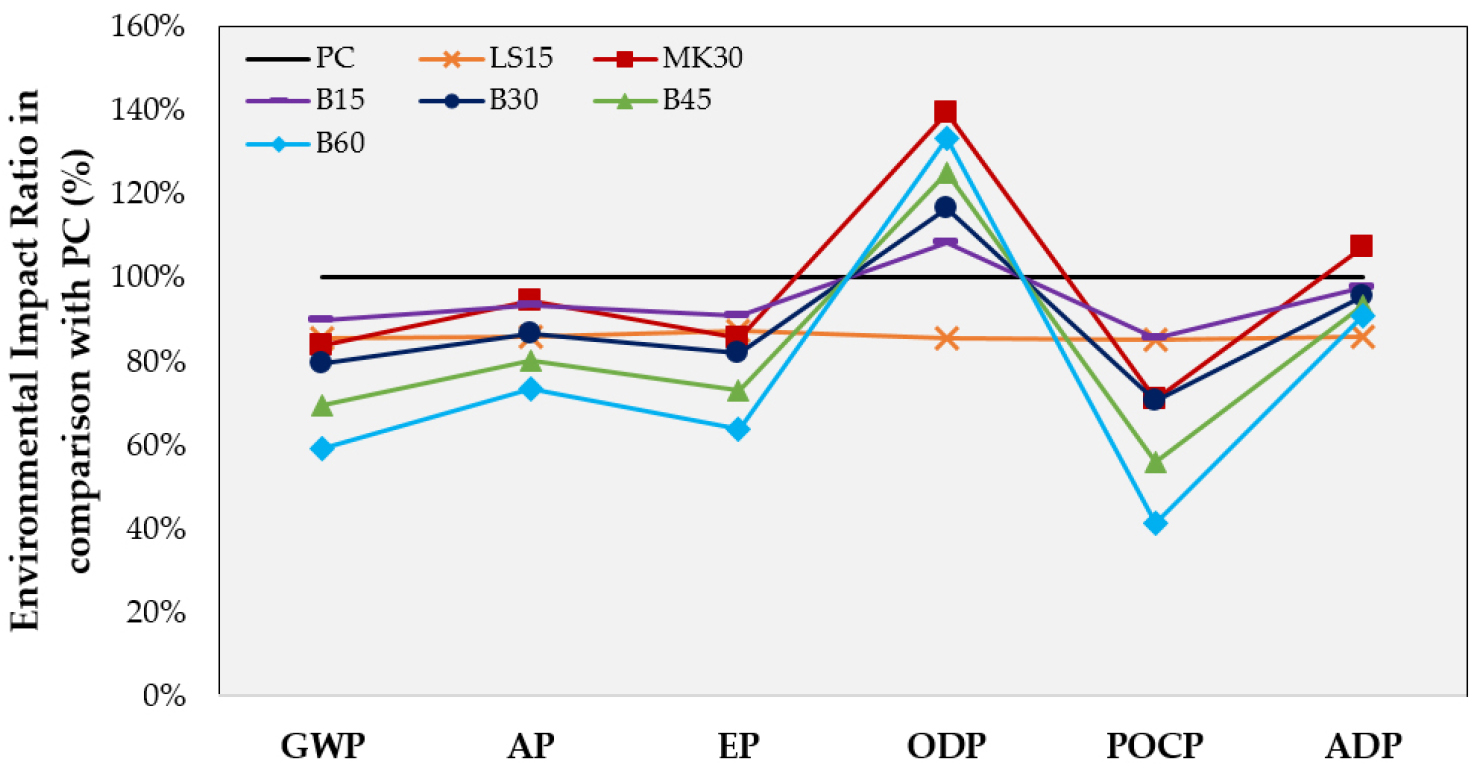

Figure 2 and Figure 3 respectively present the evaluation results of GWP and the environmental impact ratios, as well as the analysis of environmental impact trends. According to Figure 2 and Figure 3, except for LS15 without metakaolin inclusion, all mixtures showed higher ODP compared to PC. This analysis attributes this to the higher impact of metakaolin compared to cement in terms of ODP. Additionally, the overall evaluation results indicated that EP and POCP exhibited similar increasing or decreasing trends as GWP, with MK30 being the only mixture that showed higher ADP than PC.

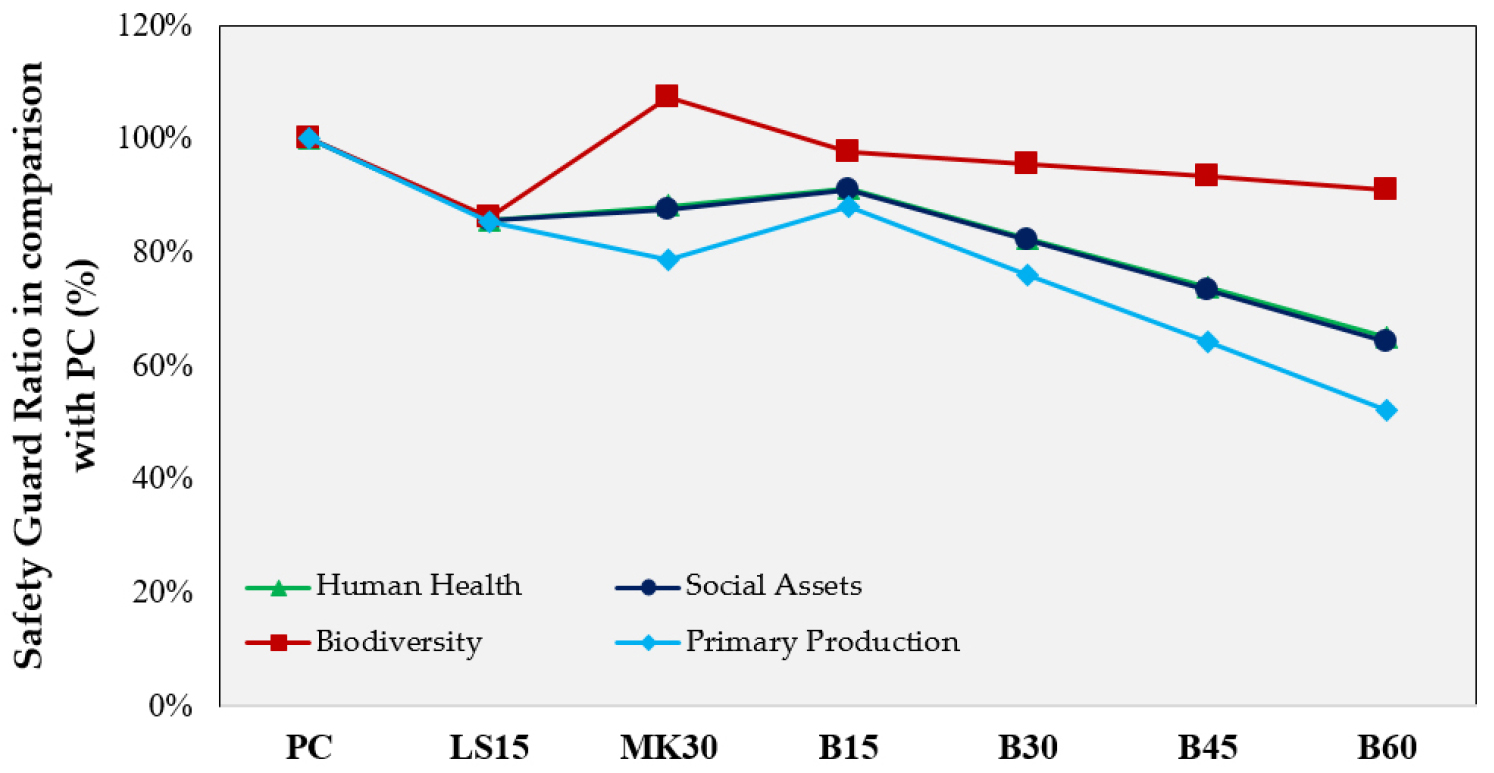

Figure 4 presents the evaluation results for safety guards, and Figure 5 illustrates the assessment outcomes for environmental costs. According to Figure 4, the overall trend for mix proportions containing metakaolin tended to be higher. This is attributed to the fact that biodiversity is directly related to ADP, and metakaolin possesses the highest impact factor in ADP. Additionally, it is noteworthy that Human Health exhibited a very similar trend to that of Social Assets.

Figure 5 reveals that environmental costs displayed a similar trend to GWP. In GWP, MK30 exhibited a lower value compared to LS15. However, in terms of environmental costs, MK30 displayed a higher value than LS15.

Conclusions

The purpose of this study was to analyze the environmental impact reduction performance of concrete using metakaolin as a substitute for cement, and the following conclusions were drawn:

1.GWP shows a strong correlation with the quantity of cement. Therefore, reducing the cement content is crucial for mitigating GWP.

2.All mixtures containing metakaolin exhibited higher ODP values than PC (Portland Cement). This is primarily due to metakaolin having the highest impact factor in ODP.

3.Metakaolin also has the highest impact factor in ADP, and ADP is directly proportional to biodiversity. Consequently, mixtures containing metakaolin tended to have a higher impact on biodiversity. Additionally, it is noteworthy that Human Health exhibited a very similar trend to that of Social Assets.

4.While metakaolin is effective in reducing certain environmental impacts, including GWP, it may be necessary to use it in combination with limestone. This is because metakaolin not only increases ODP and ADP but also has an influence on biodiversity and environmental costs.