Introduction

Materials and Method

Materials

Mix design

Curing conditions

The Experimental Program

Results and Discussions

Mechanical properties of date palm fibers:

Ultrasonic pulse velocity

Compressive strength

Flexural strength properties:

Conclusions and Recommendations

Introduction

Because of the steady increase in the cost of construction materials, and because of the environmental side effects resulting from the industry, researchers have begun to think to involve new building materials with lower cost and more environmentally friendly. Concrete is a strong material in compression and relatively brittle, weak in tension and tend to cracking and shrinkage, where the brittleness of concrete is increasing as its strength increases [1].

For this, steel reinforcement is used to resist the tension stresses. However, the steel reinforcement is costly and highly potential exposure to corrosion due to the high permeability of reinforced concrete. The scientists propose manufacturing fibers such as polyvinyl alcohol (PVA) and polypropylene fibers to replace the use of steel fibers. Despite this, manufacturing these fibers needs chemical compounds that are not considered to be sustainable materials.

Many studies have been conducted to investigate the potential possibility to employ plant wastes in concrete, as cement replacement, aggregate replacement as well as fibre reinforcement [2]. Natural fiber is one of the solutions available that can be used as an alternative to conventional fiber in cement mortar and concrete. Previously, wide range of studies were conducted on many types of natural fibers such as hemp, sugarcane bagasse, coconut, coir, sisal, banana, eucalyptus, Abaca, Cotton, Flax, Henequen, Jute, Kenaf, wheat straw, bamboo, oil palm, banana and Ramie fibers [1-5].

Natural fibers can be employed in concrete especially in developing countries and countries that need low-cost construction. In general, previous research has proven that the presence of natural fibers in concrete can improve the cracking strengths, their toughness and post-cracking performance. On the other hand, the use of natural fibers in concrete result in issues related to durability in alkaline environment [6].

A limited number of research has been conducted to study the use of date palm fiber concrete. Date palm trees grow in hot and dry climates around the world, and are more common in the Middle East, North Africa, India, the Canary Islands and the southern United States [7]. It was estimated that, the number of date palm trees is 150 million trees spread over an area of about 1.3 million hectares in 30 countries [8]. In Libya, date palm trees are distributed around the country. For example, in Al-Jufra area, the number of palm trees increase from 88 thousands in 1930s to around 3 millions in 2010 [9].

Date palm have four types of fibres, which are leaf fibre in the peduncle, baste fibre in the stem, wood fibre in the trunk and surface fibre around the trunk. Comparing with the other date palm fibre species, male date palm surface fibre (MDPSF) have the best tensile strength which range between 170-300 MPa [10]. MDPSF can be obtained from the thin tissue that covers the top of the male plant and works as an insulator to protect the palm from the vagaries of weather. In addition, usually we can get the palm fiber at the end of the reaping season. Alternatively, it is obtained after the death of Palm or during the trimming process. Date palm fiber has been used for thousands of years in many industries and perhaps surprisingly be used in wigs industry by the Pharaohs and the Romans. There are many other industries that employed the palm fiber as a basic material, which was used until recent times, such as ropes, baskets, pillows and cleaning equipment [11]. Figures 1, 2 and 3 show the date palm tree and date palm tree fiber.

The employment of MDPSF in building technologies can improve the thermal insulation performance especially in desert area regions which may contribute in reduce the energy consumption, it can be also a suitable alternative of asbestos fibres which have negative impacts on human health [12].

Similar to other vegetable fibers, the existing of MDPSF in concrete result in reduction in withdrawal of concrete [13]. Djoudi et al. [14] concluded that some vibration is essential to get suitable workability and compaction of date palm fiber concretes. The authors find out that, the present of MDPSF in the concretes improve its mechanical properties such as the compressive strength, flexural strength, ductility and cracking threshold. However, excessive fiber content results in a reduction in both compressive and flexural strengths. The length of fibers does not affect the concrete modulus of elasticity. The concrete density and the thermal conductivity reduce along with the increase of the fiber content and length [14]. However, other recent study [15] find out that the addition of MDPSF in concrete reduce its compressive properties.

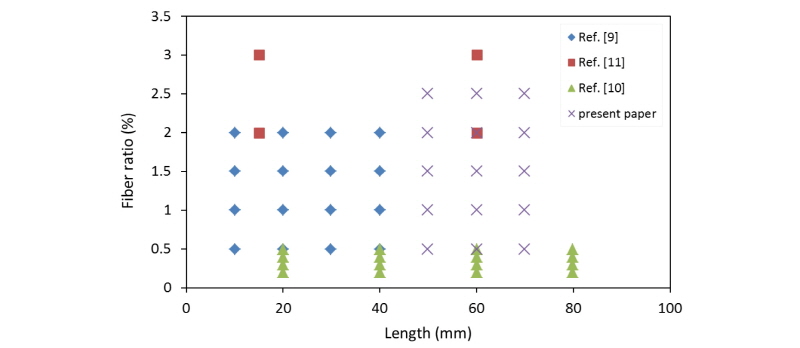

Overall, according to the previous literature, the ideal length and percentage (by mass) of MDPSF to be used in concrete is 6 cm and 0.4% respectively [15, 16]. However, there is a considerable variation on the mechanical effect on concrete after adding MDPSF. Additionally, as shown in Figure 4, the available research data is limited to specific lengths ratios of MDPSF. Therefore, further research is required into the properties of palm fiber concrete. This paper focuses on studying the mechanical behaviour of concrete containing larger lengths of MDPSF. The behaviour of MDPSF was examined as well.

Materials and Method

Materials

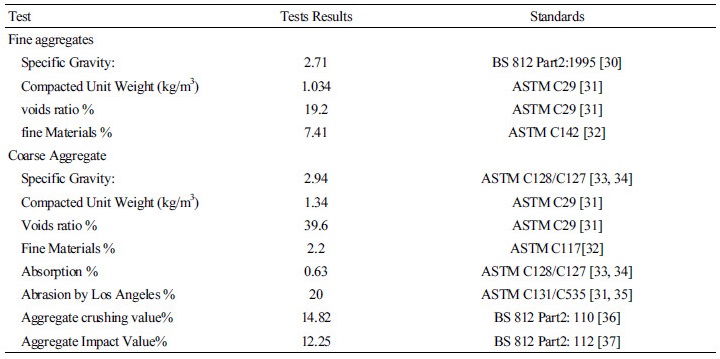

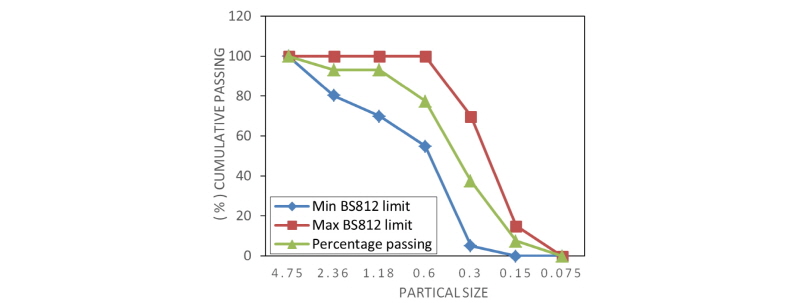

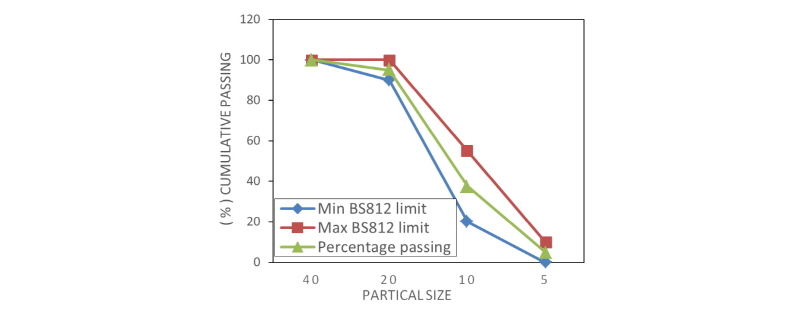

MDPSF-reinforced concrete produced consists of cement, water, aggregates with specific contents of MDPSF. Tap water was used in making and curing the specimens. In addition, Ordinary Portland cement product by Al-Burg cement plant, complying with the Libyan specification (No. 340-2009 [17]) was used in concrete mix. The cement was examined for the fineness (using sieve No. 200) and the result was: 9.3% (<22%) which complies with ASTM C 150 [18]. Natural aggregate available in Al-Jufra area was used in this research. The properties of fine and coarse aggregate are summarized in Table 1, Figure 6 and 7 illustrate the sieve analysis of sand and gravel respectively.

MDPSF preparation

The fiber used in this research was prepared through the following steps: Firstly, MDPSF was collected from one types of palm called Alkhaddray (local name). After that, the fibers were cut into specific lengths to be used in the concrete mix. Finally, the fiber was washed by passing water on it several times until saturation to avoid the absorption of mixture water by the fibers and minimize any effect on the water cement ratio.

Figure 5. Illustrate the preparation stages of MDPSF to use in the concrete mixture.

Mix design

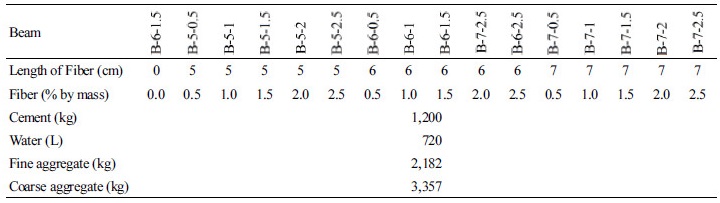

15 concrete mixtures containing different ratios and lengths of fibre were prepared. MDPSF with the dosage by mass were 0.5, 1, 1.5, 2 and 2.5% for each length of 50, 60 and 70 mm were incorporated in concrete. Fiber mass was used in this investigation as the volume of natural fibers is complex to determine due to the voids that are inherent in organic fibers as a result of natural configuration and therefore irregular shapes of the fibers. Sand gravel (S/G) ratio was taken 0.65, as suggested by Abdelmalek 2004 [15]. Trial method using slump test according to the American specifications (ASTM C143) [19], was used to design the concrete mix and get the appropriate water cement ratio (w/c = 0.6) with slump ranging between 70 and 90 mm. Table 2 illustrate the mix design proportion of concrete the specimens.

Curing conditions

The concrete specimens were firstly cured for 24 h under ordinary climatic of the laboratory, after that the concrete specimens were placed for 28 days in water.

The Experimental Program

The experimental tests included two main parts, firstly, the properties of MDPSF that include microscopic inspection, bulk density, specific gravity, water absorption, tensile strength and Young’s modulus according to ISO 527 standards [20]. Secondly, the mechanical behaviour of hardened MDPSF concrete, the following tests were conducted: (1) The compressive strength of concrete at 28 days. Cubic specimens of 15 × 15 × 15 cm were utilized (BS 1881: Part 116) [21]. (2) The flexural strength of concrete at 28 days. Specimens of 10 × 10 × 50 cm were utilized (ASTM C78) [22]. (3) The ultrasonic wave speed in concrete test at 7, 14, 21 and 28 days. Figure 8 illustrates both types of cubes and beam specimens and were tested according to the American standards (ASTM C597) [23].

Results and Discussions

Mechanical properties of date palm fibers:

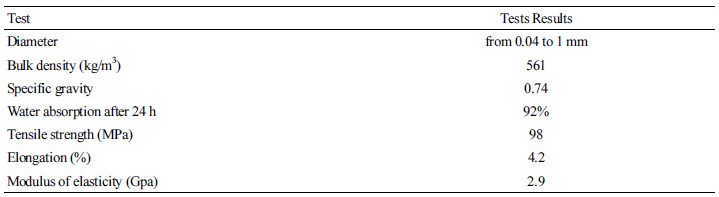

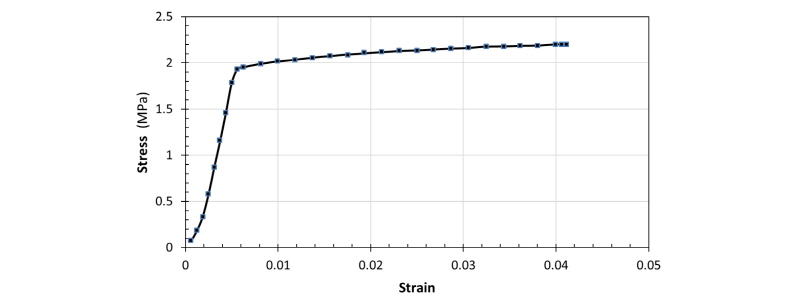

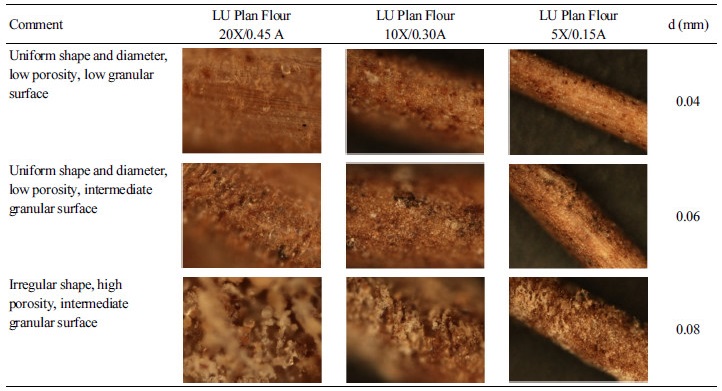

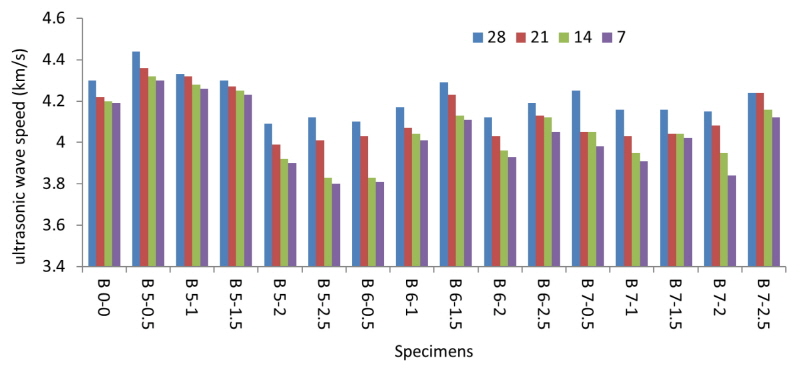

The physical and mechanical properties of date palm fibers used in this research are shown in Table 3 and Figure 9. It shows the diameters (d), density, specific gravity, absorption, tensile strength and modulus of elasticity of MDPSF used in this research. According to the microscopic examination results shown in Table 4, the fiber has a full section and it constitute very small filaments formed in layers, the disordered layers allow the flexibility of the filament. The existence of alveolar structure on the surface of the fibers guarantees a good connection between matrix and fibers.

Ultrasonic pulse velocity

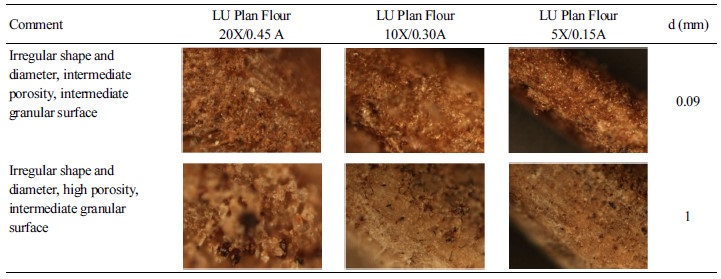

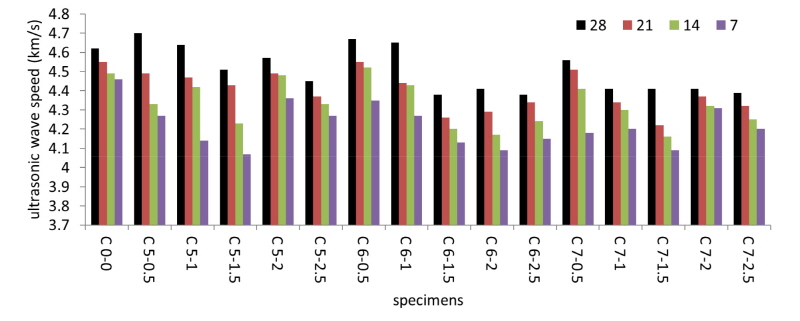

Ultrasonic pulse velocity (UPV) is one of the non-destructive tools used for assessment of concrete quality and to estimate the strength of concrete test specimens. Several previous studies (Tanigawa et al., 1984 [24]; Kheder 1999 [25]; Popovics et al., 1990 [26]; Turgut, 2004 [27]) concluded that there is a great correlation between ultrasonic pulse velocity and the compressive strength. ASTM C597 [28] and B.S.1881: Part:203 [29] describe the standard test methods for determination of pulse velocity through concrete. From Figure 10, we can see the development of ultrasonic speed with age of MDPSF concrete. This indicates the increase in compressive strength and concrete quality with age. Based on Figure 10 and 11, all of the results showed that the speed exceeds 3.5 m/s2 indicating that the concrete used is of good quality, while for the age of 28 days, all of the results exceed 4 m/s2, indicating that the concrete is of excellent quality.

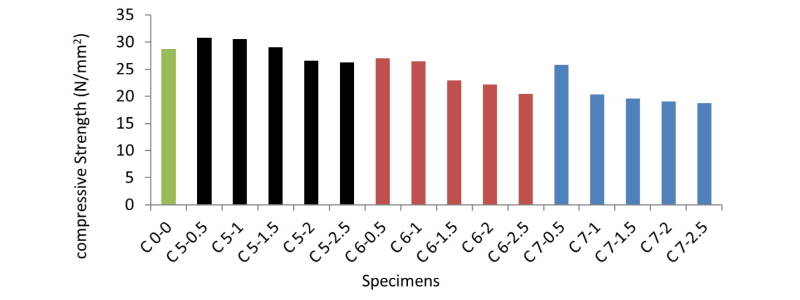

Compressive strength

The results of concrete compressive strength for lengths of 50-70 mm of MDPSF, is shown in Figure 12. Figure 12 presents the mean values for compressive strength, fiber percentage and fiber length. The results show that the compressive strength decreases with increasing fiber percentage and length. The maximum compressive strength of MDPSF-concrete occurs at 0.5%-5 cm fiber concrete, and is higher than the pure concrete (0%-0). This shows that there is uniform distribution of the 5 cm fibers at a dosage of 0.5% in the matrix. The increase in compressive strength between the concrete without fibres (0%-0 cm) and MDPSF-concrete mixture (0.5%-5 cm) is also assisted by tensile strength of the palm date fibers shown in Table 3 and the bond between the concrete and the fibres based on the alveolar structures on the surface of the fibres.

As shown in Fig. 12, the values of compressive strength decrease until the higher percentage of fiber was added (2.5%-7 cm). The optimum granular composition was much better for the length of 50mm than the other lengths, because the sizes of 50mm can better enclose the larger granulates than the fibres length of 60 and 70 mm. The workability decreases when the dosage of fibers increases. It can be noted also that the addition of fibres interrupts the mineral skeleton of the concrete, creating voids inside the matrix and increasing its porosity, by giving it a minimal strength. These observations are in agreement with the results of previous research on different fibres concretes studied.

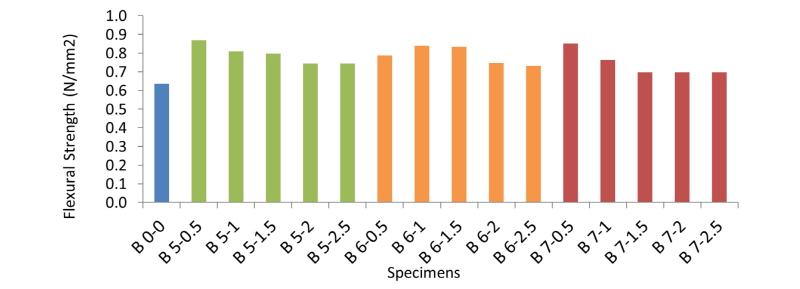

Flexural strength properties:

According to the Figure 13, it is clearly noted that the flexural strength increases considerably with dosage and length of fibres. A best improvement for 50 mm length fibers was a dosage of 0.5%, and a best improvement for 60 mm length fibers was a dosage of 1%, although this result is a misnomer when compared to the overall trend of results. The best improvement for 70 mm length fibers was a dosage of 0.5%. Similarly, due to the nature of flexural failure which is depended on the tensile strength of the materials at the extreme fibres, the increase in flexural strength between the concrete without fibres (0%-0 cm) and the MDPSF-concrete mixtures is also attributed to the by tensile strength of the palm date fibers shown in Table 3 and the bond between the concrete and the fibres based on the alveolar structures on the surface of the fibres.

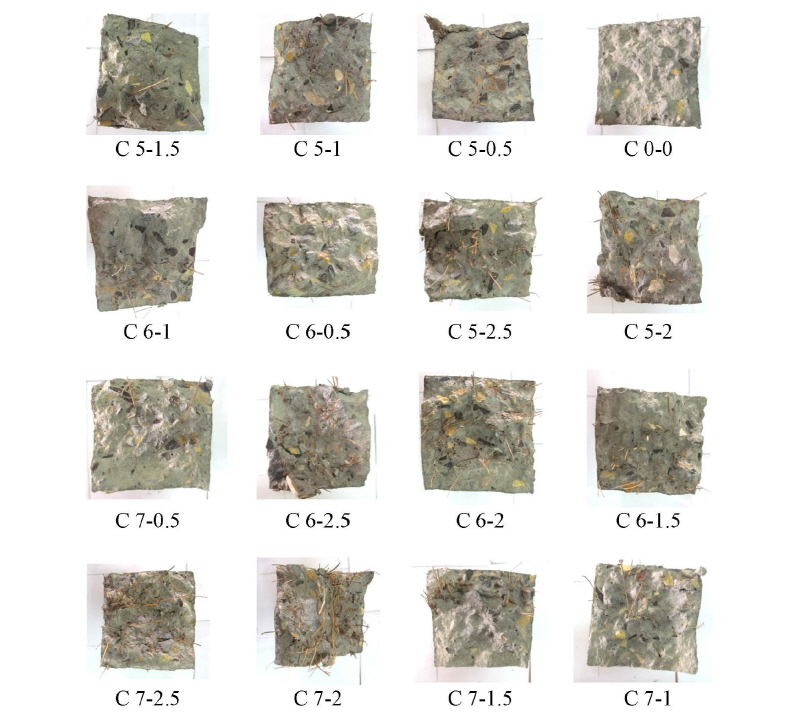

The worst flexural strength was recorded for a dosage of 2.5%-7 cm fibres owing to excess of fibres and a bad distribution of the fibres in the matrix, while increasing the porosity of the material reduces the flexural strength. These results show that greatest benefit can be obtained by adding relatively short fibers (50 mm) at minimal dosages (0.5%). This is a favourably sustainable outcome for strengthening of concrete structures to improve both compressive and flexural strength. The Distribution of date palm fibres in the beams cross section after failure is illustrated in Figure 14.

Conclusions and Recommendations

Experimental work was conducted to study the effect of male date palm surface fibers (MDPSF) on concrete mechanical properties. The properties of these fibres were also studied. The following conclusions can be made:

∙ Compared to the reference concrete, adding MDPSF to the concrete has a significant positive impact on the flexure strength. In addition, referring to the Observation of fiber microstructure, different diameters of MDPSF have a different void distribution on its surface.

∙ The best compressive strength of MDPSF concrete was achieved with 50mm length fibers at 0.5% dosage. Furthermore, based on the result of ultrasonic wave speed in the concrete beams, that the concrete quality was increased with time.

∙ Finally, after the results and observations reported in this paper, further research should be developed on the curing of MDPSF-concretes, especially in hot-dry climate and free atmosphere climate.

∙ Although the diameters of the natural fibres have been determined through microscopy, the present results show that fibre length and percentage by mass significantly influence the ultrasonic wave speed, compressive strength and flexural strength of the MDPSF-concrete mixtures. Future investigations can focus on the distribution of fiber diameters in different samples and their potential influence on the MDPSF-concrete mixtures.