Introduction

Impact assessment tools relevant to industrial site

Methodology

Selection of reference GBRS and adjustments

New category of credits

New credit specifications

The protocol

Result and Discussions

Conclusions

Introduction

Industrial sites significantly affect the quality of living environment. The impacts involve many aspects of people’s everyday landscape, ranging from negative effects on the physical ecosystem to perceptual interferences with its socio-cultural sphere. As a result, factories are reasonably synonymous with negative environmental and social impacts [1].

Since its origin the manufacturing sector has strongly stressed the ecosystem, using both renewable and non-renewable resources, significant amount of energy and releasing polluting emissions and harmful waste stream [2, [3]. Specifically, in 2018, the industry sector accounted for 37% of total global final energy use and 24% of global CO2 emissions [4]. These effects occur at both the local and global levels, and are mainly due to intensive production processes, obsolete building technical services, poor building construction techniques, and inefficient logistics [5].

Besides, industrial assets have often interfered with the visual and perceptual quality of nearby landscapes, as their development has historically been guided by profit goals rather than effective urban and territorial planning [6]. The impacts involve both site and building levels. A lack of relation is frequently recorded between site and context, and between building and its open space, as the banal, repetitive, and anonymous architectural design often affects both the image of the factory and the poor quality of indoor spaces, which are merely devoted to meeting production needs [6, 7, 8, 9, 10, 11]. All of this biases the well-being of employees and local residents too – who would not easily accept the factory disturbing their landscape [1] – but also the corporate image and the value and attractiveness of an area [12, 13].

In response to this wide range of impacts, the concept of sustainable manufacturing has gradually taken shape during the last decades, encompassing, at least theoretically, all three dimensions of sustainability (i.e. environment, economy and society). Topics in this global challenge range from energy and resource efficiency to waste reduction; from contributing to the local economy to investing in infrastructures; from fair working conditions to good community relations [14].

In the real world, several large corporations have already taken significant steps to become more sustainable, which have revealed to produce profit and improve competitiveness. While small and medium-sized businesses – representing the vast majority of industries – still have difficulties related to costs, lack of knowledge and resource to invest [14].

In general, green factories’ practices mainly focus on energy and resource efficiency at process level, which account for the main demand within the factory system: concrete actions in this area have been pushed by rising of raw material and energy prices, as well by the policies and measures established to address climate change [15, 16]. Good environmental practices at site and building level are less spread instead, although adopting an integrated approach at multiple scales is strongly envisaged by many authors [2], [17, 18]. In literature in fact the surrounding environment – such as the building, building technical services, logistics and visual interferences – increasingly emerges as an important factor to be considered as source of green opportunities [1], [19, 20]. Technical building services for example can account up to 30% of energy consumption and their operating is strongly connected with the building shell features [16].

The architectural quality of factories and related “services” therefore has gradually emerged as relevant topic, partly due to its beneficial effect on workers productivity, happiness and health [6, 11], partly due to marketing feedback on the improved corporate image [21], as well as triggered by the new concept of “visual” pollution [22]. Practices in this field are mostly at the site and building level: they are often limited to the façade, with color design used to visually mitigate the impact of both operating and new facilities [23]. Other actions focus on social activities and services for staff, local residents and visitors, leading to “multifunctional” infrastructures [24]. However, these latter are still rare and the risk to run into green washing operations is extremely high if not successfully paired with environmentally and economically sustainable actions [13]. This threat is mentioned by some authors as mere “beautification” [11] or “disneyfication” of work space [21].

It became clear that the triple bottom line of sustainable development must be addressed as a whole in order to get really sustainable factories and mitigate their effects also in daily practices. This requires concerted efforts to reduce local and global pressures on the ecosystem, increase the value of the territory, and protect workers and local communities from the industry-related disruptions such as the perceptual-aesthetic, environmental and even social interferences. Obviously, sustainable factories must be economically sound beyond being environmentally friendly [25], where this latest will be considered only a beneficial side effect by businesses [3].

Although several theoretical studies, viable strategies and practical measures to mitigate the impacts and deliver tangible benefits are being developed [15], a clear answer to what makes a factory sustainable is still pending, as it differs greatly across disciplines and approaches by academia, industry and policy-makers [16].

Impact assessment tools relevant to industrial site

The preliminary identification of major criticalities in the relationship between buildings and the environment is crucial for developing successful mitigation strategies. In other words, a clear understanding of which factory interferences contribute the most to making a production site incompatible with the context is required.

Since the subject includes diverse, interconnected, and multifaceted aspects, only an assessment procedure capable of integrating all of them can produce adequate results. Even though literature offers plenty of indicators related to sustainable manufacturing, which deal with the complexity of the topic addressing different scales and perspectives, enterprises still need appropriate metrics, methods and guidelines suitable to design and operate the eco-factory of the future [26].

Hence a review of tools available to this purpose has been performed. Valid tools exist for sustainability performance assessment at process and supply chain scales (es. Dow Jones Sustainability Index, GRI Reporting Framework, IChemE Sustainability Metrics), which are largely consolidated in theory and have already been adopted by many firms worldwide, even though according to Chen et al. [27] none is universally effective yet.

Meanwhile, Green Building Rating Systems (GBRSs) seem to emerge as viable and widespread models to assess the environmental performance of factories too. They especially focus on site and building levels, which appear to be less addressed both in literature and practice of green manufacturing. Despite being originally developed to the building scale, most of them have later expanded their scope to include a wider environmental matrix when gauging sustainability. Hence, the authors performed a review of some of the most diffused GBRSs, as detected in Sam and Wood [28]: LEED-GBC, BREEAM, CASBEE, GREEN STAR. It derives that the general LEED scheme is widely adopted by enterprises worldwide [29] and, although the U.S. Green Building Council does not offer a specific factory scheme, a LEED User Group for Industrial Facilities (LUGIF) is already supporting the adaptation of the general protocol [30], while the Indian Green Building Council has launched in 2009 the first Green Factory Building scheme [31]. Similarly, both the British BREEAM [32] and Japanese CASBEE [33] have general schemes applicable to factory, while the Australian GREEN STAR offers a specific scheme [34]. An additional search for GBRSs relevant to manufacturing site has been undertaken, from which results that also the German DGNB has an Industrial Site scheme [35], as well as the Italian Protocollo Itaca[36]. However, these latest have fewer applications, and are mainly limited to their respective countries of origin.

Nevertheless GBRSs specifically address the environmental sphere of sustainability, while the cultural and social impact of factories on people’s everyday landscape is often overlooked: for each selected scheme, the share of credits referring to perceptual-aesthetic interferences with the surrounding has been estimated by searching the occurrence of keywords such as “amenity,” “open space,” and “external view” within the credits list. The results range from 0% matching credit in BREEAM to 11% in DGNB, going through the 7% of U.S. LEED.

In parallel a review of landscape and visual impact assessment tools applied to industrial facilities was conducted. Approaches and procedures developed both by academia and policy makers to evaluate the impact of human interventions on the landscape are highly heterogeneous, due to the blurred notion of landscape itself [37]. Perceptual interferences are typically estimated using participatory methods (i.e. surveys and workshops), whereas aesthetic and visual impact is frequently measured using indicators derived from digital models (i.e. GIS) [38]. Given the complexity of the matter, the search for industry-specific assessment tools returned few results. Some relevant studies have thus been assumed as references, with a focus on those conducted in the Mediterranean region. In particular: a procedure developed by the province of Milano (Italy) to evaluate and mitigate the impact on the landscape of different constructive typologies, which includes industrial sites [39]; a study by University of Torino which delivered guidelines for industrial landscape in the Sardinia region (Italy) [40] and an European project aimed at estimating the landscape quality of different “minor” sceneries, among which the industrial one [7]. In addition, the rich literature on energy infrastructures [24], [41, 42, 43] as well as that on rural settlements [44, 45, 46] have been considered as reference assuming that these interventions are similar to factories in size and kind of impact.

In summary, the literature review reveals a variety of mostly monodisciplinary assessment protocols, each designed to resolve particular problems but unable to address the problem as a whole, even though scientists and researchers are increasingly advocating for an integrated approach.

Methodology

This paper outlines the method and summarizes the main results of a study aimed at developing a tool to evaluate the impact of factories on their surroundings, thus assisting companies to find what makes them more sustainable. The project is part of a larger research on factory landscape compatibility, with the overall goal of providing firms with a simple but efficient procedure for detecting their impact on the context and then mitigating the negative effects as much as possible, while also increasing their competitiveness as virtuous, sustainable, and appealing factories. The resulting ‘protocol’ consists of an assessment system and a catalogue of good practices that companies and designers may use to reduce the effect of both existing buildings and new constructions. Academics will benefit from the findings as well, as the study pave the groundwork for a more complete landscape impact assessment of industrial facilities.

The article focuses on the assessment system and specifically builds on new constructions due to the broader range of options these make available. The method is broken down into three principal steps:

1. Selection of the reference GBRS (LEED) and detection of its gaps to the scope of the research;

2. addition of a new credit category to make LEED more suitable to the overall landscape assessment of factories, thus addressing Perceptual-Aesthetic aspects (PA);

3. description of new PA credits into proper cards, providing end-user with a guide to evaluate that specific impacts.

The novelty of the study stems primarily in the integration of a well-established GBRS with perceptual aesthetic aspects in order to make it more comprehensive and take advantage of the positive synergies among different landscape aspects, that can reduce the impact and improve firm profit-making.

Selection of reference GBRS and adjustments

Since GBRSs have proven their effectiveness in gauging impacts of different types and returning a global index of sustainability, and since they are increasingly being used for industrial facilities, the idea is to build on this basis an expanded rating system that can measure the overall impact of manufacturing sites. Therefore, a critical comparison of the aforementioned GBRSs was conducted, and the most suitable for research purposes was chosen by comparing the credits list of those schemes with a list of recurring impacts of factories retrieved from the literature [47].

The U.S. GBC LEED v4 Building Design and Construction scheme was chosen for its best trade-off between percentage of credits referable to cultural and social sustainability issues (7% connected with perceptual aesthetic aspects); global diffusion and ease of use [48]; number of already certified green factories [30]; possibility to easily add new credits or even new topic categories [49].

Then a thorough analysis of the selected LEED scheme was conducted to determine which adjustments are needed to make it appropriate for a holistic assessment of green factories. As foreseeable, the major gap is the lack of indicators to measure the visual, perceptual and social interferences of factories with their surroundings. There are only few credits (4 out of 58) that potentially cover this kind of impact, namely: ‘Surrounding density and diverse uses’ (Location and Transport category); ‘Open Spaces’ (Sustainable Site ctg.); ‘Daylight’ and ‘Quality views’ (Environmental Indoor Quality ctg.). These credits, however, are far from being adequate to measure the effects of manufacturing sites on the landscape and social sphere.

New category of credits

A set of additional fitting credits was thus proposed, basing on general items of landscape and visual assessment [50]. The few research related to factories and the research projects about energy infrastructures [24], [41, 42, 43] and rural buildings [44, 45, 46] were also assumed as reference.

The list of new credits and their objectives is shown in Table 1: they span from Site assessment which is mandatory to get a clear understanding of the context, to credits which investigate the physical consistency of the factory compared with landscape aesthetic perceptual components retrieved by Tudor [51]. Further credits address the interference of the project with the social component of living environment (workers, local inhabitants, consumers, visitors).

Table 1.

List of new credits

A testing phase is envisaged for these eight new credits: according to the U.S. GBC LEED rules they could be included within the Pilot Credit Library, from which additional credits can be freely selected by the design team and inserted in the Innovation category (IN) of whichever LEED scheme [52]. However, this GBC procedure allows for a maximum of 5 points to be earned by pilot credits [53]. Therefore, the research proposes moving a step further and enhancing the LEED scheme with a brand-new category - ‘Perceptual-aesthetic aspects (PA)’ - collecting the eight additional credits and adding on the LEED existing ones (Figure 1).

A score was then given to the new credits following the LEED point allocation process, which assigns each credit with one or more points basing on its relative effectiveness to accomplish the rating system goals [49]. This calculation is performed by a weighted average, like it is for all the LEED credits. It derives that higher scores are assigned to credits that contribute the most in achieving the more important LEED goals [54]. Table 2 shows the weighting process for the new PA credits, where ‘PA0 - Site assessment’ is not included being mandatory (according to the LEED notation, it is a ‘prerequisite’).

Table 2.

Weighting of PA new credits

New credit specifications

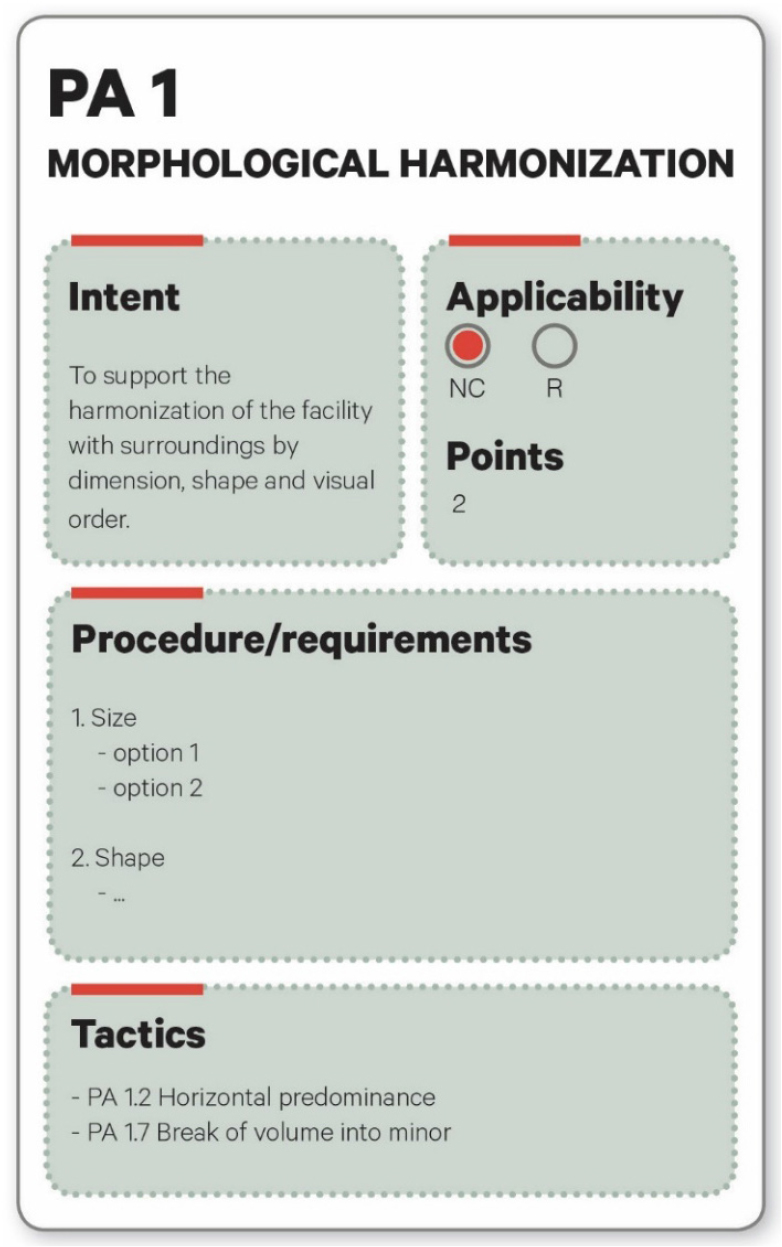

The LEED User Manual is referred to specifying the “original” credits used in the rating protocol, while new but similar cards have been developed for PA credits. These worksheets provide information that can be used to measure the credit related performance and get a score (Figure 2). In particular:

- whether it is valid for New Construction and/or Existing Building;

- achievable points;

- intent of the credit;

- procedure, indicators and means that can be used to assess the impact;

- tactics that can be implemented to eliminate, mitigate or compensate the impact.

The central section of each card deserves further explanation, since some credits contain more than one topic related to the landscape sub-components. For example, the credit ‘PA 1 - Morphological harmonization’ is to be evaluated according to the relation between the building size, its shape and visual order with the corresponding landscape features.

Moreover, each credit is associated with at least one indicator suitable to measure it: this can be quantitative, qualitative or semi-quantitative depending on the nature of the specific impact to assess. As the Perceptual-Aesthetic features highly depend on personal judgments and individual preferences [37], more than one assessment ‘option’ is provided: these may be chosen on a case-by-case basis depending on the available information, evaluation scope, timing, or design constraints. References to external guidance or assessment methods are given when necessary.

The protocol

In addition to the LEED scheme thus variated - called ‘Rating System’ – the research also delivered a ‘Catalogue of good practices’. While the first outcome is a tool to determine the most relevant interferences of a factory with the context, the latter consists in a repertoire of projects and best practices of impact mitigation in manufacturing sites, which can inspire firms and designers to adopt suitable and effective strategies for this purpose.

The case studies included within the repertoire have been retrieved from a great variety of sources (from scientific literature to company web sites; from design competitions to architectural magazines). The search was focused on manufacturing facilities that used outstanding practices at both the physical and management levels to: (i) minimize their negative impact on the physical environment; (ii) reduce aesthetic and perceptual interferences with the scenery; (iii) support the wellbeing of workers and local communities.

As previously mentioned, a library of general mitigation tactics was extracted from the Catalogue of Practices and integrated with the Rating System by linking each credit to associated tactic(s). This couple of tools forms a protocol that companies can use to determine what makes a plant environmentally, socially, and economically sustainable.

Lastly, the protocol has been tested on Orogel, an Italian leading agri-food company, which is currently expanding its manufacturing site. Starting from the approved project, the application led to define and compare three mitigation scenarios with increasing compatibility level. The lower one, which primarily implements surface and beautification strategies, scored 42/127 points: this can equate to the LEED level 'Certified,' suggesting that the improvement is acceptable but not outstanding. For the higher level, instead, the implemented sustainable holistic practices on existing facilities are also combined with a volumetric extension that visually mitigate the complex, whereas non-mitigable environmental and social problems are compensated too. This results in 79/127 points (comparable to LEED ‘Gold,' the second highest level).

Result and Discussions

The developed Rating System consists of ten assessment categories: the original nine LEED categories plus the new PA category. The version for new construction now has 12 prerequisites and 50 credits, of which 1 and 7 belong to the additional PA category, respectively, while the number of credits in the version for existing buildings is reduced to 42.

The full version for new construction thus includes 16 additional points, raising to 127 the maximum achievable score from the original 110. The PA category has a relative weight of 13,4% within this points amount, which is close to 12,6% accounted to both the Location and Transport and the Environmental Indoor Quality categories, and it is about half of the reasonably most important category Environment and Atmosphere (26%). Since the LEED process to weigh credits is clear but complex, some approximations have been made at this stage, whose effect do not however affect the development of a commercial product. Some adjustments and tuning could be required for overpassing the long and strict approval path by U.S. GBC committee, which is the precondition to the adoption of the proposed new LEED version.

Nevertheless, the cases documented in the Catalogue of Good Practices and the Orogel test demonstrated that the proposed approach is suitable, as it conforms to the principles for sustainable factory adopted globally. In fact, the case repertoire shows that higher levels of sustainability are achieved when practices from different categories are combined. Similarly, the Orogel application demonstrated that higher compatibility level with the context is achieved more effectively when mitigation tactics from diverse fields are implemented together.

Being the three dimensions of sustainability across multiple scales properly encompassed within the developed rating protocol, the interlaced topics and issues are more likely to being intercepted and turned into opportunities for both firms and territories. Thus the tool helps companies to successfully detect what make their factory more sustainable, and it suggests possible actions to be undertaken to this end.

Conclusions

The paper provides the theoretical background around landscape compatibility of factories as well as the main issues companies have to deal with in daily practice to reach this purpose. Lack of knowledge and economic constraints are often recognized as key barriers to create sustainable and pleasant factories. Therefore, the impact identification is envisioned as a powerful procedure to drive the change, especially when combined with the provision of strategies to minimize their effects and boost corporate image. Since the available tools to evaluate the impacts seem inadequate to holistically address the subject, the study has proposed a changing to an effective, globally recognized rating system such as LEED, which by nature allows for content enhancement and updating. This yields a modified LEED scheme with an eight credits new category devoted to assess the perceptual-aesthetic interferences of factories with the landscape. The impact this change can have on the path to green factories is significant, as it provides a structured methodology that includes perceptual and social mitigation practices in line with many authors’ recommendations. Furthermore, since it has a large impact on corporate image, this change will help the long-term economic sustainability of businesses.

Given that the assessment of certain credits requires specialized expertise, the depicted Rating System can be difficult to apply for businesses, thus the protocol effective implementation will need the help of designers and practitioners. Thus further developments can be suitably targeted to making the impact measurement simpler and faster by non-technicians, as well as the identification of successful mitigation practices.

All in all, the broader research from which this article derives suggests that the key to get really sustainable factories is not to make pretentious projects that exhibit to be something different from they actually are. Rather, the route should be to effectively balance the needs for production and profit with environmentally sustainable activities and triggering social benefit. As taking care of workers is, as well as enhancing local community health and wellbeing and being attractive to customers and visitors. From a sustainable holistic perspective, this can produce a win-win situation for both businesses and territories.