Introduction

With the increasing concern regarding global warming, which is caused by climate change, the environmental importance of contemporary structures such as sustainable buildings with an extended service life is increasing. As the need for reducing the environmental load has come to the fore in the construction industry, contemporary buildings are being adapting by application of green design techniques and development of new technologies [1, 2]. Builders are attempting to create a life cycle impact assessment system that surpasses environmental load, and embraces transportation, construction, maintenance, management, and disposal of materials used in buildings [3, 4]. Due to the increasing demand for a low carbon building system, practical technology needs to be employed to evaluate the greenhouse gas emissions of buildings. This requires studies on the creation of greenhouse gas emission for each life cycle stage of buildings. Among such studies, quantitative environmental impact assessment is particularly necessary to calculate the increase in service life of structures and reduction in environmental load according to maintenance technologies. Accordingly, this study aims to create a life cycle greenhouse gas database and comparatively analyze the different composition ratios of a cement reactive siloxane polymer-based compound and penetration resist agent using polysiloxane, applied for surface protection in construction, where a penetration resist agent is applied to extend the service life of buildings. In this study, basic data and LCI DB(Life Cycle Inventory Database) for raw materials of the cement reactive siloxane polymer-based penetration resist agent as well as isophorone diisocyanate, ethylene glycol, and polydimethylsiloxane were secured to evaluate greenhouse gas emission of the penetration resist agent.

Method

Overview

This study aims to evaluate the life cycle greenhouse emission of a cement reactive siloxane polymer-based compound and penetration resist agent using polysiloxane, according to the optimal composition ratios. To develop the basic unit of greenhouse gas emission of the cement reactive siloxane polymer-based penetration resist agent, basic data and LCI DB for raw materials were secured. An evaluation program called TOTAL (Tool for Type III Labeling and LCA) was used to evaluate the greenhouse gas emission of each type of the siloxane polymer-based penetration resist agent [5]. The scope of this evaluation on the optimal composition ratios (two oil types, two water types) of the new penetration resist agent included six greenhouse gases defined by the IPCC; they are carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), hydrofluorocarbons (HFCs), perfluorocarbons (PFCs) and sulfur hexafluoride (SF6).

Material

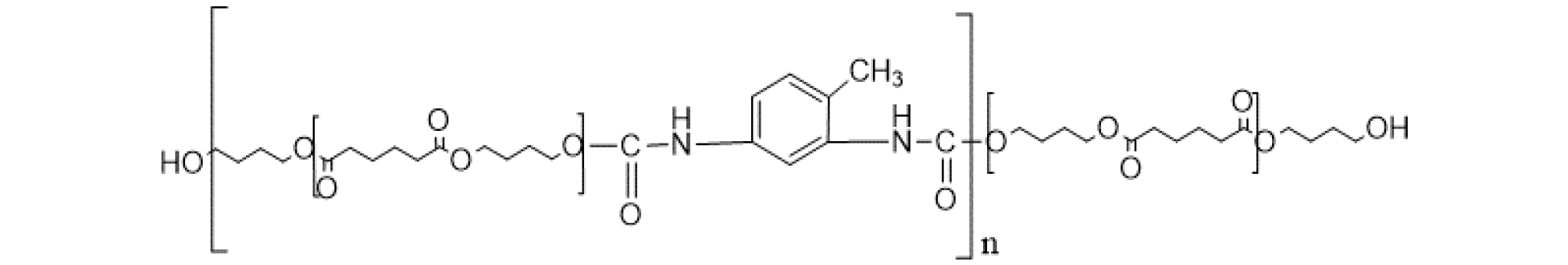

The target materials of this study were selected to be cement reactive siloxane polymer-based penetration resist agents that have high reactivity on the surface modified by silane and siloxane, large molecular weight, excellent durability. As seen in Figure 1, The target materials were produced by synthesizing spherical urethane polymer and melamine prepolymer[6] .

In this study, cement reactive siloxane polymer-based penetration resist agents that have high reactivity on the surface modified by silane and siloxane, large molecular weight and excellent durability made by synthesizing spherical urethane polymer and melamine prepolymer were selected as the test targets (refer to Table 1, Figure 2). The components of the penetration resist agent such as melamine, paraformaldehyde, poly (dimethyl siloxane) and tetraethyl orthosilicate were analyzed as shown in Table 2 according to the ratio of anti-absorption materials, such as dimethyl carbonate, naphtha (petroleum), hydrodesulfurized heavy, water and polyvinyl alcohol used in the penetration resist agents [7, 8].

Table 1. Polyurethane prepolymer sample list

Table 2. Classification of materials for evaluation / test target

Melamine is an industrial chemical known as triazine triamine. It is a heterocyclic organic amine base produced by heating urea, the latter is synthesized using ammonia and carbon gas. About 66% of its mass is composed of nitrogen, and it has an ability to withstand fire when mixed with resin. Melamine is sparingly soluble in hot water, slightly soluble in cold water and ethanol, and insoluble in ether. It is used as a raw material for plastics, fertilizers, dyes, adhesives and electronic circuit boards along with formaldehyde. Paraformaldehyde is a polymer formed by reacting formaldehyde with ozone. This polymer is a white powder, obtained by concentrating formaldehyde solution It emits a weak odor of formaldehyde and generates a strong irritant odor when heated. Poly dimethyl siloxane (PDMS) is a transparent inert substance that corresponds to a polymer organic silicide. It is the most widely used among the organic silicon polymers because of stable adhesion to a relatively wide area. It exhibits penetrability with various liquids and vapors. Tetraethyl orthosilicate (TEOS) is a colorless liquid that dissolves in water. It has lower density than water and its vapor is heavier than air. TEOS is mainly used as a crosslinking agent of silicon polymers and as a precursor of silicon dioxide in the semiconductor industry. Dimethyl carbonate (DMC) is a colorless, transparent and irritant liquid at room temperature and can be mixed with almost all organic solvents including alcohol, ketone and ester at any ratios. DMC is slightly soluble in water. In addition, DMC is a green chemical that can replace low toxic solvents such as toluene, xylene, ethyl acetate, butyl acetate, acetone, butanone and other solvents in the paint and adhesive industries. Polyvinyl alcohol (PVA) is a water-soluble synthetic resin that is a thermoplastic and has oil resistance. PVA is used as a chemical to increase the viscosity of films and adhesives. It is mainly used to manufacture peel-off packs due to its excellent ability to form films. PVA is also used to stabilize emulsions using the colloid effect.

Evaluation of Greenhouse Gas Emission

For greenhouse gas emission evaluation, the environmental impact of the system was evaluated comprehensively by estimating quantitative and qualitative effects on the environment based on LCA. LCA is a method of quantitatively evaluating resources, energies and environmental pollutants during the life cycle (production, assembly, transportation, use, maintenance, disposal, etc.) of a product. It is used as a tool to promote the reduction of environmental load and achieve sustainable development [9, 10, 11, 12].

Classification

Classification is a process in which items derived in the inventory analysis are classified into impact categories. The impact categories to be considered in LCA are determined by classification. Classification is largely divided into two stages. The first stage is to qualitatively link the inventory items to their environmental impact based upon known facts from the literature. The second stage is to gather all inventory items linked within the same impact category. The resulting classification shows how the inventory items affect the environment.

Characterization

Characterization refers to the process of quantizing the effects of items in an impact category on the impact category. In other words, characterization is a method of showing potential contribution of the inventory factors classified into each impact category using equivalency factors. It is represented by the equation (Eq. 1). Global warming is a phenomenon in which the mean surface temperature of Earth increases. The primary cause of global warming is the emission of greenhouse gases like carbon dioxide. Carbon dioxide (CO2) is the reference substance for global warming, and there are 23 impact substances including methane (CH4), nitrous oxide (N2O), hydrofluorocarbons (HFCs) and sulfur hexafluoride (SF6) refer to Table 3. Global warming is calculated using the value of carbon dioxide (CO2), the reference substance, by applying environmental load of the impact substances to the Global Warming Potentials (GWPs) provided by the International Panel on Climate Change (IPCC).

Table 3. Global Warming Potentials (mass basis)

| $$\mathrm{Global}\;\mathrm{Warming}\;\mathrm{Potentials}\;=\sum_{}^{}Load_{(i)}\times GWP_{(i)}$$ | (1) |

Here, Load(i) is environmental load of the impact substances (i) classified in the environmental impact category and GWP(i) is the Global Warming Potential for the substance i.

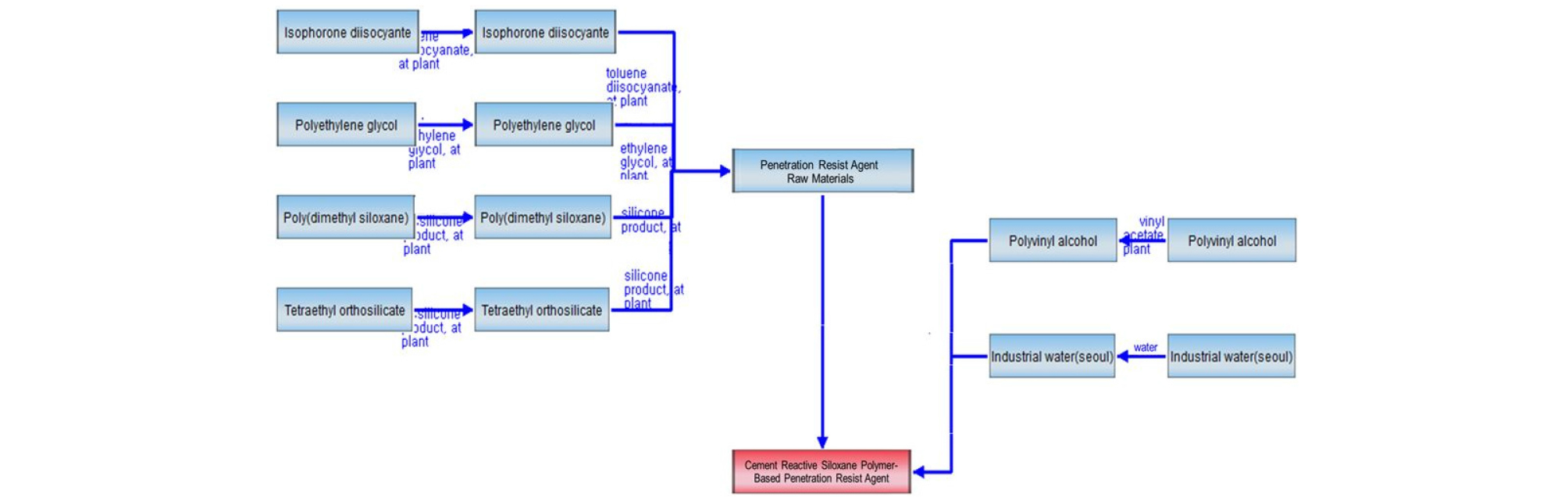

The life cycle CO2 emission test of the target product was performed by applying the basic unit of CO2 emission for the raw materials used to make the siloxane polymer-based penetration resist agent. Figure 3 shows the process flow chart of the siloxane polymer-based penetration resist agent. Greenhouse gas emission was evaluated using an LCA software program supported by the Ministry of Environment called TOTAL.

Result

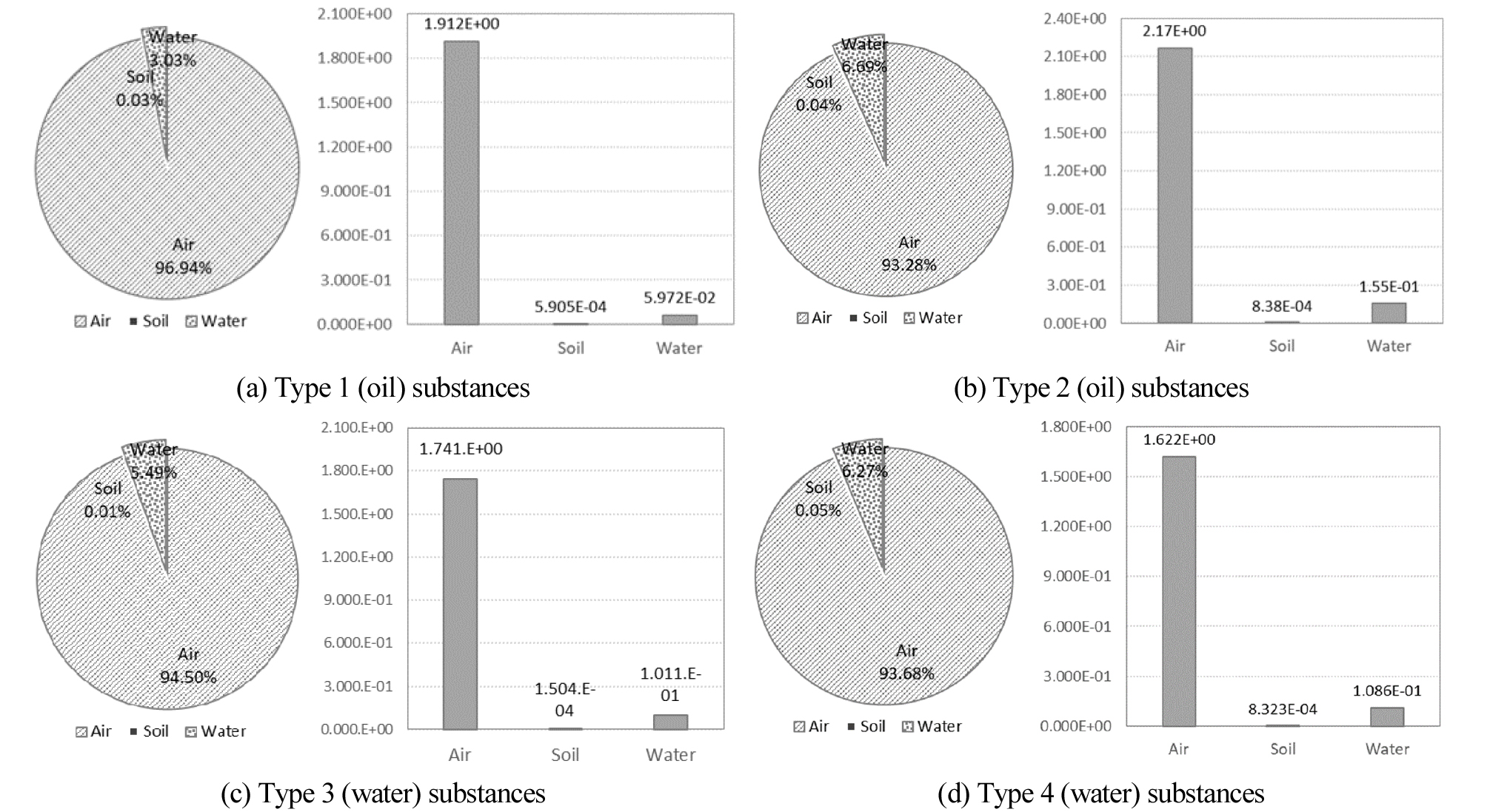

As seen in Figure 4, based on the analysis of the type 1 (oil) substances of the siloxane polymer-based penetration resist agent, the total environmental impact of emission was 2.14 E+00 kg-CO2eq/m2. Among them, high ratios of greenhouse gas emission were shown in the order of atmospheric pollution (1.96 E+00 kg-CO2eq/m2), soil pollution (3.00 E-04 kg-CO2eq/m2) and water pollution (1.45 E-01 kg-CO2eq/m2). Atmospheric pollution showed the highest contribution (91.71%) in the overall environmental emission.

Based on the analysis of the type 2 (oil) substances of the siloxane polymer-based penetration resist agent, the total environmental impact emission was 2.28 E+00 kg-CO2eq/m2. Atmospheric pollution emission, soil pollution, and water pollution were 2.17 E+00 kg-CO2eq/m2, 8.38 E-05 kg-CO2eq/m2, and 1.55 E-01 kg-CO2eq/m2, respectively. Atmospheric pollution showed the highest contribution (93.28%) in the overall environmental emission.

On the other hand, analysis of the type 3 (water) substances of the siloxane polymer-based penetration resist agent showed that the total environmental impact emission was 1.94 E+00 kg-CO2eq/m2. The atmospheric, soil and water pollution were 1.91 E+00 kg-CO2eq/m2, 5.90 E-04 kg-CO2eq/m2, and 5.97 E-02 kg-CO2eq/m2 respectively. Atmospheric pollution showed the highest contribution (96.94%) in the overall environmental emission. Lastly, based on the analysis of the type 4 (water) substances of the siloxane polymer-based penetration resist agent, total emission was 1.68 E+00 kg-CO2eq/m2. The atmospheric pollution, soil pollution, and water pollution were 1.91 E+00 kg-CO2eq/m2, 5.90 E-04 kg-CO2eq/m2, and 5.97 E-02 kg-CO2eq/m2, respectively. Atmospheric pollution showed the highest contribution (96.94%) in the overall environmental emission. The ratios of greenhouse gas emissions were found in the order of atmospheric pollution, soil pollution and water pollution for all four types of the product. The ratio of atmospheric emission exceeded 90% in all types.

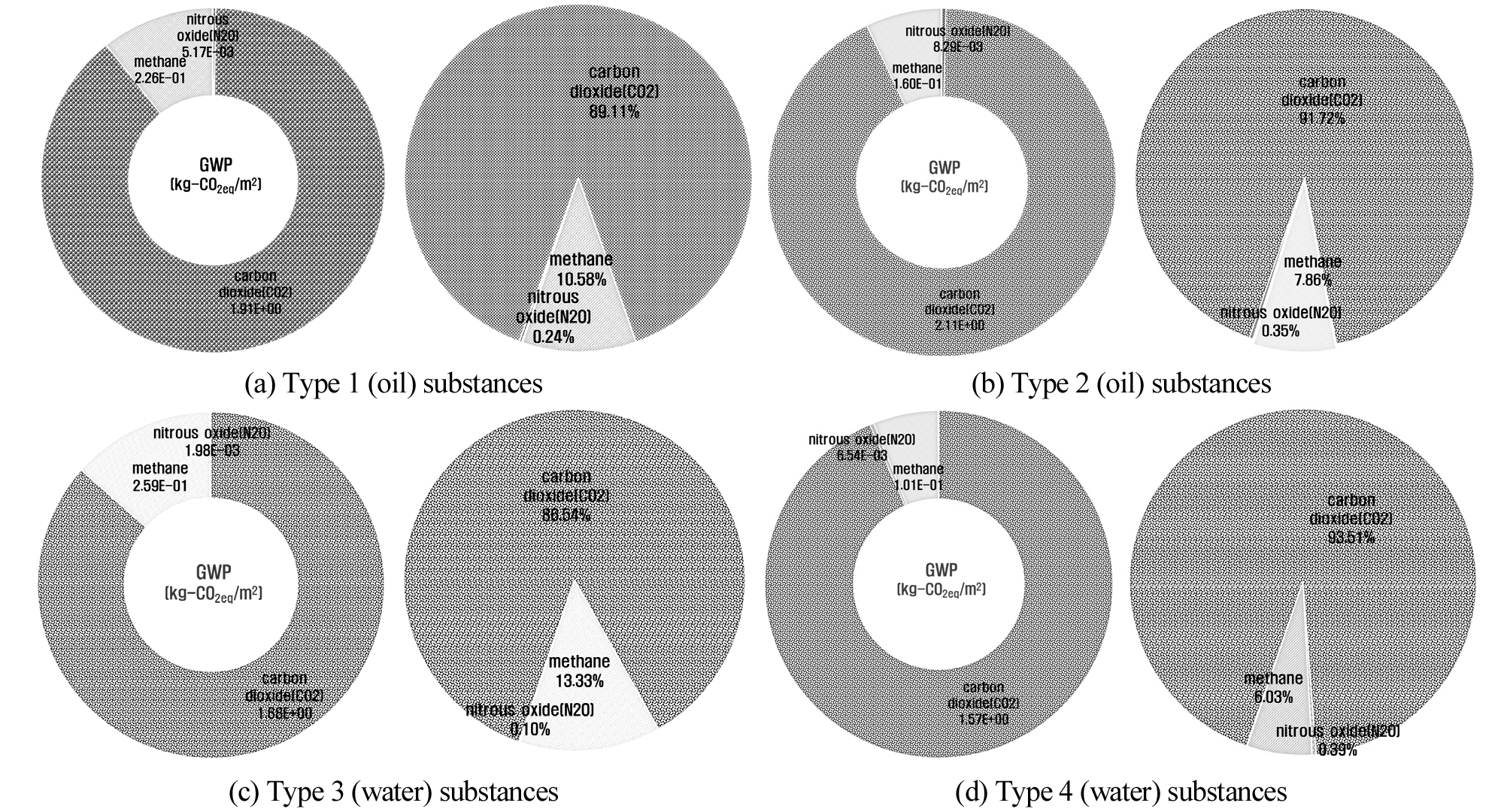

Global warming is a phenomenon in which mean surface temperature of the earth increases. The primary cause of global warming is the emission of greenhouse gases including carbon dioxide. Carbon dioxide (CO2) is the reference substance for global warming, and there are 23 impact substances including methane (CH4), nitrous oxide (N2O), hydrofluorocarbons (HFCs) and sulfur hexafluoride (SF6). For the target product of this evaluation, carbon dioxide (CO2) was found to have the most significant impact on global warming among the impact substances.

According to this evaluation, the carbon dioxide (CO2) emission (1.68 E+00 kg-CO2eq/m2) showed the highest contribution (93.51%) in the overall emission of 1.94 E+00 kg-CO2eq/m2. Methane (CH4) with an emission of 2.59 E‒01 kg-CO2eq/m2 showed a high contribution of 6.03%, as presented in Figure 5.

Conclusions

This study aimed to evaluate greenhouse gas emission of different types of the cement reactive siloxane polymer-based penetration resist agent using polysiloxane, and the conclusions are as follows.

1.For the life cycle greenhouse as evaluation on the optimal composition ratios (2 oil types, 2 water types) for the siloxane polymer based new chemical compound and penetration resist agent, the scope of the life cycle greenhouse gas emission analysis was defined as six greenhouse gases defined by the IPCC including carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), hydrofluorocarbons (HFCs), perfluorocarbons (PFCs) and sulfur hexafluoride (SF6).

2.Based on the analysis of type 1 (oil), type 2 (oil), type 3 (water) and type 4 (water) of the siloxane polymer based penetration resist agent, the total emissions were 2.14 E+00 kg-CO2eq/m2, 2.28 E+00 kg-CO2eq/m2, 1.94 E+00 kg-CO2eq/m2 and 1.68 E+00 kg-CO2eq/m2, respectively. The ratios of greenhouse gas emissions were found in the order of atmospheric pollution, soil pollution and water pollution for all the four types.

3.Based on the analysis of the mean greenhouse gas emission ratio of the target product, carbon dioxide (CO2) showed an emission of 1.57 E+00 kg-CO2eq/m2 and the highest contribution of 93.51%. Methane (CH4) showed an emission of 1.01 E-01 kg-CO2eq/m2 and a high contribution of 6.03%.

4.Based on the analysis of greenhouse gas emission for water materials of the siloxane polymer-based penetration resist agent, greenhouse gas emission of water materials was lower than emission of oil materials. Among them, type 4 (water) showed the lowest greenhouse gas emission. According to the results of this evaluation, it is recommended to use a green chemical product composed of the type 4 (water) material when making a cement reactive siloxane polymer-based penetration resist agent using polysiloxane.